Choosing the Right PVC Pipes for Your Project: A Detailed Analysis

Choosing the Right PVC Pipes for Your Project: A Detailed Analysis

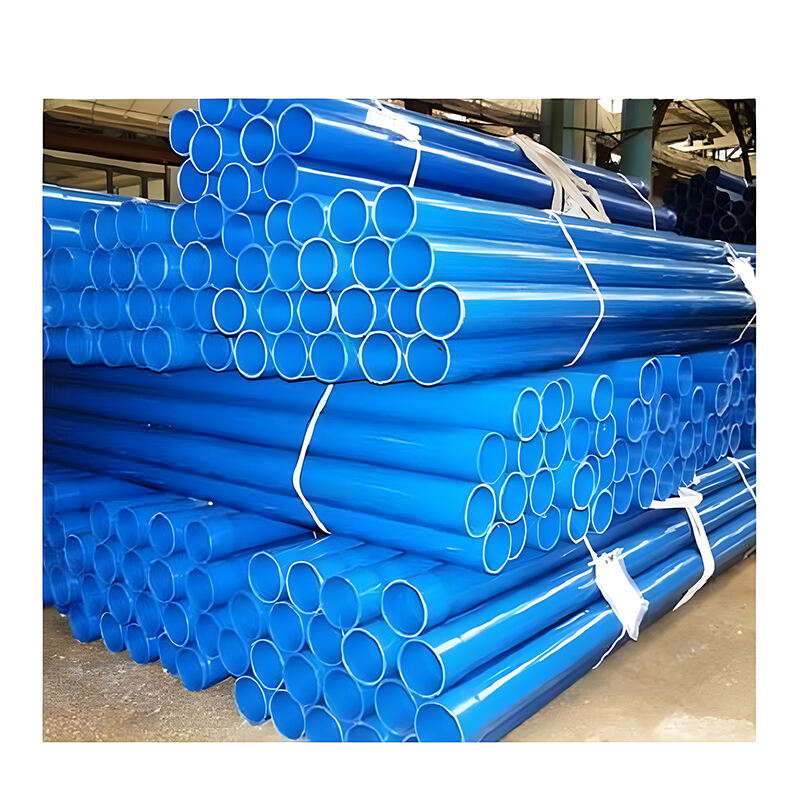

The success of any plumbing or piping system depends largely on the choice of materials. Selecting the wrong type of pipe can result in higher maintenance, reduced service life, or even system failure. Over the past few decades, PVC Pipes have become one of the most widely used materials in both residential and commercial projects. They are known for their durability, cost-effectiveness, and adaptability across a wide range of applications. However, because there are different classes and types of PVC Pipes, the process of selecting the right one for a project requires a clear understanding of their properties, limitations, and installation requirements.

Understanding the Basics of PVC Pipes

PVC stands for polyvinyl chloride, a thermoplastic polymer that has been used in the construction industry since the mid-20th century. Its popularity in piping systems is due to a combination of features including resistance to corrosion, lightweight handling, and ease of installation. Unlike metal pipes that may rust or degrade over time, PVC Pipes remain chemically stable in contact with water, soil, and many industrial fluids. They also have smooth internal surfaces that prevent scaling and maintain hydraulic efficiency. Because of these characteristics, they are used in everything from household plumbing to irrigation systems, industrial fluid handling, and municipal water distribution networks.

Types of PVC Pipes and Their Applications

One of the most common classifications of PVC Pipes is by wall thickness and pressure rating, such as Schedule 40 and Schedule 80. Schedule 40 pipes are the most frequently used in residential and light commercial plumbing. They are cost-effective, easy to work with, and capable of handling moderate pressure levels. In contrast, Schedule 80 pipes have thicker walls and higher pressure ratings, making them suitable for industrial settings where mechanical stress and higher operating pressures are expected. The choice between these two often depends on whether the system will carry potable water under pressure, be part of an irrigation system, or serve as an industrial conduit.

In addition to schedule classifications, there are pipes designed specifically for non-pressurized systems, such as DWV pipes, which stand for drain, waste, and vent. These are optimized for gravity-based systems where carrying away wastewater and venting sewer gases are the primary functions. For outdoor installations and drainage, pressure-rated PVC Pipes are often preferred because they withstand soil pressure and potential traffic loads when buried underground. Specialized PVC Pipes are also manufactured with UV stabilizers or additional coatings to improve performance in outdoor environments where long-term sunlight exposure might otherwise degrade the material.

Joining Methods and Installation Considerations

How PVC Pipes are joined is another important factor in system performance. The two most common methods are solvent cement welding and gasketed joints. Solvent cement chemically fuses the pipe and fittings into a single continuous system. When done correctly, this method produces watertight joints that are as strong as the pipe itself, making it ideal for residential plumbing and irrigation systems. Gasketed joints, on the other hand, rely on mechanical seals and are often used in larger diameters, municipal water mains, and sewer systems. They allow for a degree of flexibility in installation and can accommodate minor shifts in soil or ground movement without leaking.

Proper installation practices are essential to achieving the long service life that PVC Pipes are capable of providing. Pipes must be cut cleanly with square edges to ensure tight joints. When solvent welding is used, surfaces must be properly prepared, cleaned, and coated with primer and cement before being joined. In underground installations, adequate trench preparation is necessary, including a bedding layer of sand or fine gravel to prevent point loads that could deform the pipe. Above-ground installations require adequate support spacing to prevent sagging, especially in systems that carry pressurized water. Pressure testing after installation ensures that the system is leak-free and compliant with project specifications.

Environmental and Performance Considerations

PVC Pipes perform well in most environments, but certain conditions can influence their performance. One important factor is temperature. PVC is best suited for cold and moderate temperature water systems. Continuous exposure to hot fluids above sixty degrees Celsius can weaken the material and reduce its lifespan. For hot water systems, CPVC, or chlorinated polyvinyl chloride, is generally recommended instead. Another consideration is UV exposure. Prolonged direct sunlight can degrade PVC unless the pipe is specifically manufactured with UV-resistant additives or installed with protective coverings.

In terms of chemical resistance, PVC Pipes are extremely reliable. They resist most acids, bases, and salts, making them suitable for industrial wastewater and chemical transport in addition to potable water. This chemical stability ensures that water quality is not compromised in domestic systems and that the pipes can withstand aggressive environments in industrial applications.

Cost and Lifecycle Analysis

Cost is often one of the strongest arguments in favor of PVC Pipes. They are significantly less expensive than metal alternatives such as copper or ductile iron, both in terms of material and installation. Because they are lightweight, they reduce transportation costs and can be handled easily by small work crews without heavy machinery. The joining methods are simple, requiring no welding equipment or specialized skills beyond basic training. These factors reduce both labor costs and project timelines.

While the initial material cost is low, the long-term lifecycle benefits are even more significant. PVC Pipes require little maintenance, resist corrosion, and have a service life of fifty years or more in most applications. Reduced leakage, fewer repairs, and minimal need for replacement all contribute to long-term cost savings. For municipalities and industries managing large infrastructure, this translates into lower operational costs and improved system efficiency.

Sustainability and Environmental Impact

Sustainability has become a key concern in modern construction. PVC Pipes contribute positively because they are recyclable and long-lasting. Their extended service life reduces the need for frequent replacements, conserving resources and minimizing waste. Because they are lightweight, transportation emissions are lower compared to heavier materials such as concrete or metal. Additionally, their resistance to corrosion and scaling eliminates the need for chemical treatments, reducing environmental impact during their use phase. When projects aim to meet green building certifications, the use of PVC Pipes supports both economic and environmental objectives.

Conclusion

Choosing the right PVC Pipes for a project involves more than simply selecting a material off the shelf. Factors such as type, pressure rating, installation environment, joining method, and long-term maintenance must all be considered. Schedule 40 is suitable for most residential and light commercial uses, while Schedule 80 provides the extra strength required in industrial systems. DWV pipes serve non-pressurized drainage and venting needs, and specialized UV-resistant versions are available for outdoor applications. When correctly chosen and installed, PVC Pipes offer decades of reliable service at a fraction of the cost of traditional alternatives. They are not only cost-effective but also environmentally sustainable, making them one of the most versatile piping solutions available today.

FAQ

What does PVC stand for?

It stands for polyvinyl chloride, a thermoplastic polymer widely used in construction and piping systems.

What are the main types of PVC Pipes?

The most common types include Schedule 40, Schedule 80, and DWV pipes, each designed for different pressure and application requirements.

Can PVC Pipes be used for hot water?

They are not recommended for hot water above sixty degrees Celsius. For such applications, CPVC is more suitable.

How long do PVC Pipes last?

With proper installation and use, they can last fifty years or more.

Are PVC Pipes safe for drinking water?

Yes, certified PVC Pipes are safe for potable water systems and do not affect water quality.

How are PVC Pipes joined?

They are commonly joined using solvent cement welding for smaller systems and gasketed joints for larger installations.

Do PVC Pipes require much maintenance?

They require very little maintenance compared to metal alternatives, mainly periodic inspections.

What are the limitations of PVC Pipes?

They are not ideal for high-temperature systems or for prolonged unprotected exposure to sunlight unless UV-resistant versions are used.

Are PVC Pipes environmentally friendly?

Yes, they are recyclable, long-lasting, and reduce the need for chemical treatments, contributing to sustainability goals.

Where are PVC Pipes most commonly used?

They are used in residential plumbing, municipal water supply, sewage and drainage systems, irrigation networks, and industrial fluid transport.