HDPE Double Wall Corrugated Pipe vs Krah Pipe: Durability Test

HDPE Double Wall Corrugated Pipe vs Krah Pipe: Durability Test

In modern infrastructure projects, the demand for reliable and durable piping systems continues to grow as cities expand, industries require resilient materials, and sustainability concerns push engineers to choose cost-effective yet long-lasting solutions. Among the most widely used plastic piping systems are HDPE Double Wall Corrugated Pipe and Krah Pipe. Both are manufactured from high-density polyethylene, offering corrosion resistance, flexibility, and chemical stability, but they are designed differently to address specific needs. Comparing their durability provides valuable insights for engineers, contractors, and policymakers making decisions on water management, sewage conveyance, and industrial piping systems.

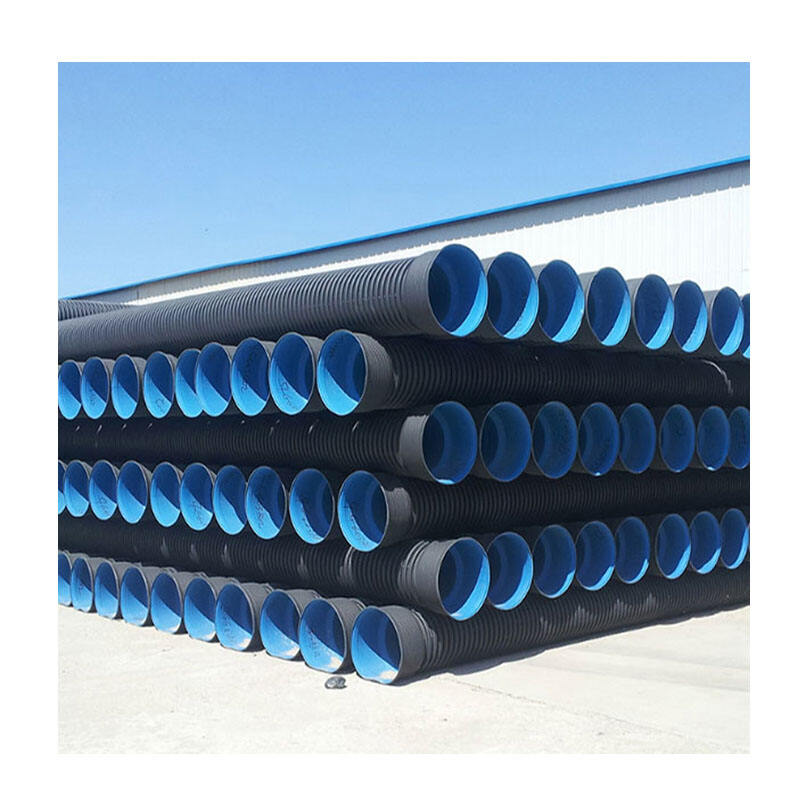

Understanding HDPE Double Wall Corrugated Pipe

HDPE Double Wall Corrugated Pipe is manufactured with a corrugated outer wall and a smooth inner wall. The corrugated exterior provides strength and resistance to external soil loads, while the smooth interior ensures efficient hydraulic performance by reducing friction losses. This dual-wall design makes it ideal for stormwater management, sewage systems, culverts, and drainage applications where structural integrity and flow capacity must be balanced.

These pipes are lightweight compared to concrete or metal alternatives, which reduces transportation and installation costs. They also offer excellent resistance to chemicals and corrosion, making them particularly suited to environments with aggressive soils or wastewater exposure. The typical jointing method involves bell-and-spigot connections with rubber gaskets or external couplers, ensuring leak resistance and easy installation.

Understanding Krah Pipe

Krah Pipe is another product made from high-density polyethylene, but it is manufactured using a helical extrusion process that creates large-diameter pipes with a customizable profile wall structure. The design allows for reinforcement through ribs or other structural profiles, giving engineers flexibility in balancing weight, stiffness, and performance. Krah Pipe is primarily used for large-diameter applications such as stormwater management, sewage conveyance, outfalls, and industrial pipelines.

Unlike HDPE Double Wall Corrugated Pipe, which is produced in standard sizes and designs, Krah Pipe can be custom manufactured to meet specific project requirements. It can reach diameters of up to several meters, making it suitable for mega infrastructure projects. Its jointing methods often involve electrofusion or butt fusion welding, creating strong, homogenous connections that are leak-proof and reliable.

Durability Factors in Plastic Piping Systems

Durability in piping systems depends on several key factors, including resistance to external loads, long-term structural stability, chemical resistance, joint performance, and resistance to environmental degradation. Both HDPE Double Wall Corrugated Pipe and Krah Pipe share inherent benefits due to their polyethylene composition, but their structural designs influence performance in different ways.

Structural Strength

HDPE Double Wall Corrugated Pipe relies on its corrugated outer wall for strength. This design distributes soil and traffic loads effectively when buried underground, making it suitable for applications such as road culverts or stormwater systems. However, its performance is closely tied to proper installation, particularly backfilling and compaction, which ensure the soil-pipe interaction provides maximum support.

Krah Pipe, with its customizable profile wall, allows engineers to design pipe stiffness to match specific load conditions. For projects requiring very large diameters and high ring stiffness, Krah Pipe can be manufactured with reinforced ribs or thicker profiles. This makes it particularly advantageous in projects where pipe stiffness and load-bearing capacity are critical.

Hydraulic Efficiency

The smooth inner wall of HDPE Double Wall Corrugated Pipe ensures efficient hydraulic performance, minimizing sediment buildup and maintaining flow rates. Krah Pipe also provides smooth internal surfaces, and due to its ability to be manufactured in very large diameters, it often achieves superior flow capacities for large-scale sewage or stormwater projects.

Joint Integrity

Jointing is a critical factor in durability. HDPE Double Wall Corrugated Pipe typically uses bell-and-spigot or coupler joints with gaskets. While these provide adequate leak resistance, they depend heavily on installation quality. Poor alignment or gasket misplacement can reduce effectiveness.

Krah Pipe often relies on fusion welding, such as butt fusion or electrofusion. These methods create joints as strong as the pipe itself, eliminating weak points and ensuring long-term leak-free performance. This advantage is particularly valuable in pressurized or high-demand systems where joint integrity is crucial.

Chemical and Corrosion Resistance

Both pipe types benefit from the inherent properties of HDPE. They are resistant to a wide range of chemicals, including aggressive soils, wastewater, and industrial effluents. Unlike concrete or steel, they do not corrode, which makes them highly durable in challenging environments.

Environmental and UV Resistance

For above-ground applications, HDPE materials can be sensitive to ultraviolet radiation over long periods. HDPE Double Wall Corrugated Pipe and Krah Pipe are typically buried, which mitigates this issue. However, when exposed, protective measures such as UV stabilization additives or coverings should be used to maintain durability.

Durability Testing in Practice

Durability testing for both HDPE Double Wall Corrugated Pipe and Krah Pipe often involves several standardized evaluations.

Deflection Testing

Pipes undergo deflection testing to measure how much they deform under load. HDPE Double Wall Corrugated Pipe is designed to flex slightly under soil pressure, with the surrounding soil providing additional support. Excessive deflection indicates improper installation or inadequate backfill. Krah Pipe, with its customizable wall profile, can achieve higher ring stiffness values, reducing deflection under heavy loads.

Hydrostatic and Leakage Testing

Water-tightness is tested by hydrostatic pressure tests or air pressure tests. For HDPE Double Wall Corrugated Pipe, gasketed joints are tested for leaks under specified pressures. For Krah Pipe, fusion-welded joints undergo hydrostatic pressure testing to confirm they are leak-proof and structurally sound.

Long-Term Stress Testing

Both types are subjected to long-term creep and stress relaxation tests, which measure performance under sustained loads. These tests confirm that the materials maintain integrity over decades of use.

Abrasion Resistance

In sewage and stormwater systems where grit and debris are common, abrasion resistance is critical. Both HDPE Double Wall Corrugated Pipe and Krah Pipe demonstrate high resistance to abrasion compared to concrete, making them durable in such applications.

Applications Where Durability Matters Most

HDPE Double Wall Corrugated Pipe is most widely used in municipal drainage, stormwater systems, culverts, and agricultural irrigation. Its lightweight structure, ease of handling, and cost-effectiveness make it ideal for projects where quick installation and reliable performance are needed.

Krah Pipe is often chosen for very large-scale projects such as marine outfalls, massive sewage systems, and industrial pipelines requiring diameters beyond standard corrugated pipes. Its durability and ability to provide fusion-welded joints make it suitable for demanding environments where joint integrity and structural stiffness are critical.

Conclusion

Both HDPE Double Wall Corrugated Pipe and Krah Pipe are durable, versatile, and highly reliable solutions for modern infrastructure. Their polyethylene composition provides excellent resistance to corrosion, chemicals, and abrasion, while their structural designs address different project needs. The corrugated double-wall structure of HDPE pipes offers a balance of strength and cost-effectiveness, making it a practical choice for municipal and agricultural systems. Krah Pipe, with its customizable design and fusion-welded joints, excels in large-diameter applications where durability and leak-free performance are paramount.

The choice between the two often comes down to project scale, design requirements, and budget. For standard municipal drainage or sewage systems, HDPE Double Wall Corrugated Pipe provides excellent performance at a competitive cost. For mega projects demanding extreme stiffness, large diameters, and superior jointing methods, Krah Pipe offers advantages that justify its higher initial investment.

FAQ

What is the main difference between HDPE Double Wall Corrugated Pipe and Krah Pipe?

The main difference lies in their design. HDPE Double Wall Corrugated Pipe has a corrugated outer wall and smooth inner wall, while Krah Pipe is manufactured using a helical extrusion process that allows for large diameters and customizable wall profiles.

Which pipe has better joint integrity?

Krah Pipe often has stronger joints because it uses fusion welding, while HDPE Double Wall Corrugated Pipe typically uses gasketed joints that depend more on installation quality.

Which pipe is better for municipal drainage systems?

HDPE Double Wall Corrugated Pipe is generally better for municipal drainage due to its cost-effectiveness and ease of installation.

Can both pipes handle sewage and industrial effluents?

Yes, both are resistant to chemicals and corrosion, making them suitable for sewage and industrial applications.

Which pipe lasts longer in buried conditions?

Both pipes can last over 50 years with proper installation, but Krah Pipe’s customizable stiffness and welded joints may provide an advantage in high-demand conditions.

What type of testing is used to evaluate durability?

Deflection testing, hydrostatic pressure testing, long-term stress tests, and abrasion resistance evaluations are commonly used.

Are both pipes suitable for large-diameter projects?

Krah Pipe is more suitable for extremely large diameters, while HDPE Double Wall Corrugated Pipe is generally limited to smaller standard diameters.

Which pipe is easier to install?

HDPE Double Wall Corrugated Pipe is easier and faster to install due to its lightweight design and gasketed joints.

Do both pipes require UV protection?

Yes, when exposed above ground, both require UV protection unless UV-stabilized materials are used.

Which pipe provides better long-term value?

For standard municipal projects, HDPE Double Wall Corrugated Pipe provides better cost-to-value balance. For mega projects requiring exceptional durability and stiffness, Krah Pipe provides superior long-term value.