PPR Pipe Complete Guide: Cost, Fittings & Installation Tips

Understanding Modern Plumbing Solutions with PPR Technology

The plumbing industry has witnessed a revolutionary transformation with the introduction of PPR pipes. These Polypropylene Random Copolymer pipes have become increasingly popular in both residential and commercial applications, offering superior durability and cost-effectiveness compared to traditional piping materials. As more contractors and homeowners seek reliable plumbing solutions, PPR pipe systems continue to gain traction in the global market.

The innovative composition of PPR pipes makes them particularly suitable for hot and cold water distribution systems. Their unique molecular structure provides excellent resistance to high temperatures and pressure, while maintaining structural integrity over decades of use. This comprehensive guide will explore everything you need to know about PPR pipes, from their fundamental characteristics to installation best practices.

Essential Components of PPR Piping Systems

Core Materials and Manufacturing Process

PPR pipes are manufactured using high-quality polypropylene random copolymer resins. The production process involves advanced extrusion technology that ensures uniform wall thickness and precise dimensional accuracy. These pipes undergo rigorous quality control measures to meet international standards for drinking water systems and heating installations.

The material composition includes specialized additives that enhance UV resistance, thermal stability, and overall durability. Modern PPR pipes are typically produced in three layers, with the middle layer containing fiber reinforcement for added strength and reduced thermal expansion.

Available Sizes and Specifications

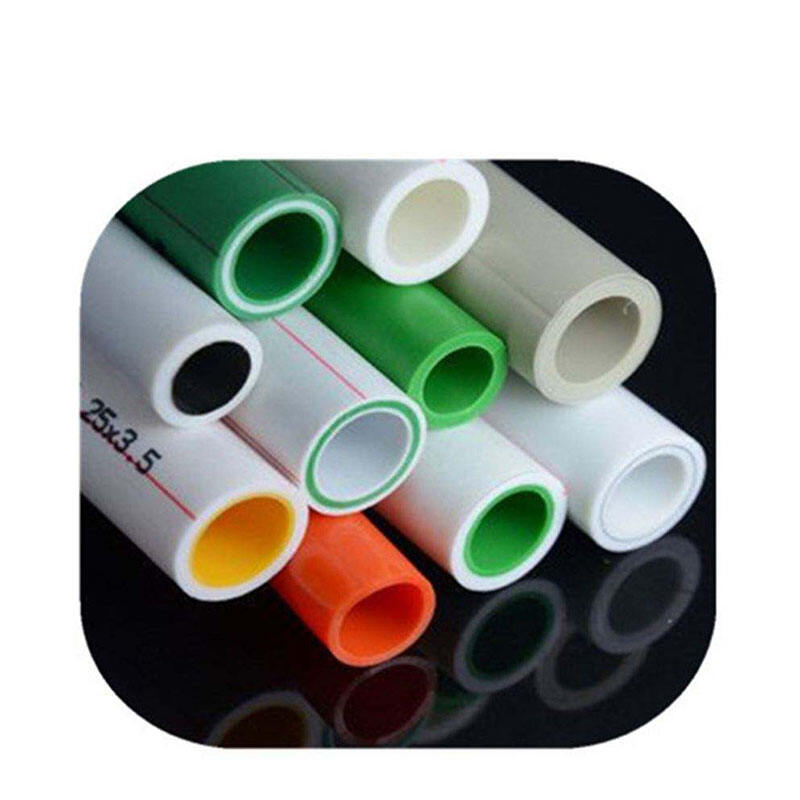

PPR pipe systems come in various diameters ranging from 20mm to 110mm for standard applications. Wall thickness varies according to pressure ratings, with options available for different operating pressures from PN10 to PN25. This versatility allows for precise matching of pipe specifications to specific project requirements.

Color coding is often used to distinguish different pipe applications, with green being the most common for potable water systems. Grey or white variants may be used for specialized applications or to meet specific regional preferences.

Cost Analysis and Economic Benefits

Initial Investment Considerations

When evaluating the cost of PPR pipe systems, it's essential to consider both material and installation expenses. While the initial material cost might be higher than traditional alternatives like PVC, the total project cost often proves more economical due to several factors. The lightweight nature of PPR reduces transportation and handling costs, while the fusion welding process eliminates the need for expensive joining materials.

A typical residential installation might require an investment of $3-5 per linear foot, including fittings and labor. However, prices can vary significantly based on pipe diameter, pressure rating, and local market conditions.

Long-term Value and Maintenance Savings

The extended service life of PPR pipes, often exceeding 50 years, translates into significant long-term savings. These systems require minimal maintenance and are highly resistant to corrosion, scaling, and chemical degradation. The smooth interior surface maintains optimal flow rates throughout the system's lifetime, contributing to energy efficiency in pumping applications.

Operational costs are further reduced due to excellent thermal insulation properties, which minimize heat loss in hot water applications. This energy efficiency can result in noticeable savings on utility bills over time.

Professional Installation Techniques

Proper Tools and Equipment

Successful PPR pipe installation requires specific tools designed for fusion welding. Essential equipment includes pipe cutters, fusion welding machines, measuring tools, and cleaning materials. Professional-grade welding machines typically cost between $200-1000, depending on capacity and features.

Quality tools ensure precise cuts and proper fusion joints, which are crucial for system integrity. Investment in proper equipment pays off through reduced installation time and superior joint quality.

Step-by-Step Installation Process

The installation begins with careful planning and layout of the piping system. Pipes must be cut square and clean, with proper allowance for thermal expansion. The fusion welding process involves heating both the pipe and fitting to the correct temperature, typically around 260°C, before joining them together.

Critical attention must be paid to heating times and insertion depths to achieve proper fusion. The joint must be held steady during the cooling period to ensure optimal strength. Proper support and anchoring systems should be installed to accommodate thermal movement and maintain system stability.

Maintenance and Troubleshooting Guidelines

Preventive Maintenance Strategies

Regular inspection of PPR piping systems helps identify potential issues before they become serious problems. Key maintenance activities include checking for proper support, monitoring for signs of physical damage, and ensuring proper operation of expansion compensation devices.

System pressure and temperature should be monitored regularly to ensure operation within design parameters. Particular attention should be paid to areas subject to mechanical stress or extreme temperature variations.

Common Issues and Solutions

While PPR pipes are highly reliable, occasional problems may arise. Common issues include improper fusion joints, inadequate support, or damage from external sources. Most problems can be prevented through proper installation and regular maintenance.

When repairs are necessary, the affected section can be cut out and replaced using repair couplings or socket fusion fittings. It's essential to identify and address the root cause of any failures to prevent recurrence.

Frequently Asked Questions

How long do PPR pipes typically last?

PPR pipes have an expected service life of 50 years or more when properly installed and maintained. This longevity is supported by extensive testing and real-world performance data from installations around the world.

Are PPR pipes safe for drinking water?

Yes, PPR pipes are completely safe for potable water applications. They are certified to international standards for drinking water systems and do not leach harmful substances into the water supply.

Can PPR pipes be installed outdoors?

While PPR pipes can be installed outdoors, they should be protected from direct sunlight and extreme weather conditions. UV-stabilized variants are available for exposed installations, but proper insulation and protection are recommended for optimal performance.

What makes PPR pipes better than traditional materials?

PPR pipes offer several advantages including corrosion resistance, longer service life, better thermal insulation, and noise reduction. Their fusion-welded joints eliminate the risk of leaks associated with mechanical connections, while their smooth interior surface maintains excellent flow characteristics throughout their service life.