Understanding the Versatility of PVC Pipes in Plumbing and Construction

Understanding the Versatility of PVC Pipes in Plumbing and Construction

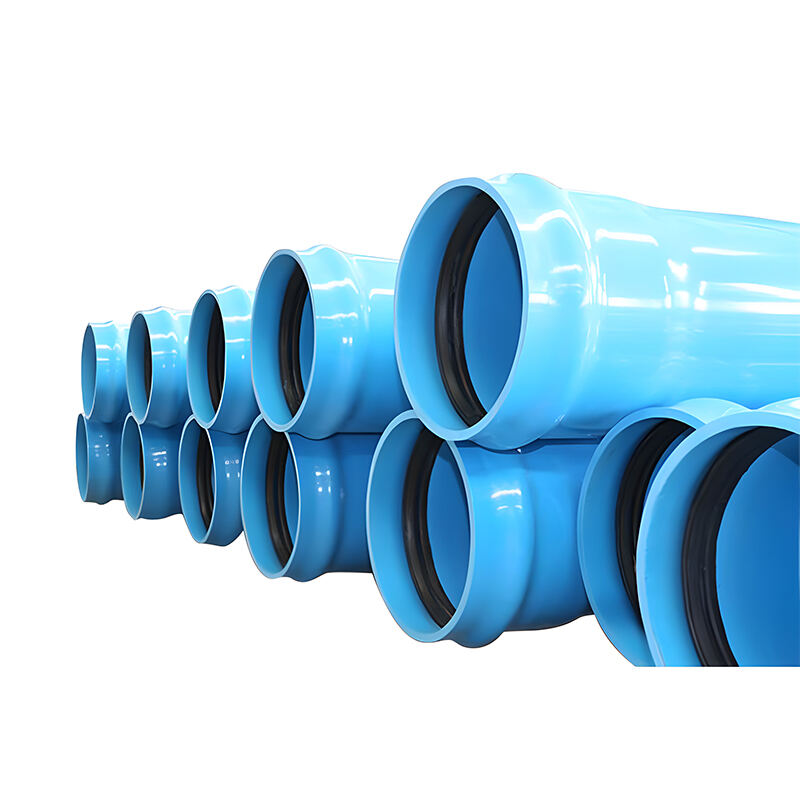

In the modern construction and plumbing industries, material choice plays a critical role in determining the efficiency, safety, and long-term reliability of systems. Among the many materials available, PVC Pipes have emerged as one of the most versatile and widely used solutions. Their adaptability across different applications, combined with their cost-effectiveness and durability, has made them a preferred choice for engineers, contractors, and homeowners alike. Understanding the versatility of PVC Pipes is essential for appreciating their role in plumbing, drainage, and construction projects that demand reliability and efficiency.

The Composition and Characteristics of PVC Pipes

PVC, or polyvinyl chloride, is a synthetic thermoplastic polymer derived from natural resources such as salt and petroleum. When processed into PVC Pipes, the material gains strength, chemical resistance, and durability while remaining lightweight compared to alternatives such as steel or copper. The smooth inner surface of PVC Pipes reduces friction losses, ensuring efficient fluid flow and minimizing blockages.

One of the most important features of PVC Pipes is their resistance to corrosion and chemical degradation. Unlike metal pipes, which are susceptible to rust and scaling, PVC Pipes maintain their structural integrity even when exposed to aggressive environments, including wastewater systems, acidic soils, and industrial chemicals. This characteristic makes them ideal for a wide range of plumbing and construction applications.

PVC Pipes are also available in different pressure classes and sizes, allowing engineers and contractors to choose the right specifications for diverse requirements, from household plumbing to large-scale municipal infrastructure. Their adaptability to different fittings and joining techniques further adds to their appeal in construction projects.

Applications of PVC Pipes in Plumbing

Residential Water Supply

In residential plumbing, PVC Pipes are commonly used for cold water distribution. Their lightweight nature makes installation easy, while their resistance to corrosion ensures that water remains clean and uncontaminated. For homeowners, this translates into low-maintenance systems that last decades without significant repairs.

Drainage and Waste Systems

PVC Pipes are widely used in drainage, waste, and vent (DWV) systems. Their smooth interiors prevent clogging, while their resistance to chemical degradation makes them ideal for carrying wastewater and sewage. The ease of installation, combined with leak-proof joints, ensures that household drainage systems remain efficient and hygienic.

Irrigation Systems

Agriculture also benefits from PVC Pipes in irrigation systems. Farmers rely on their ability to transport water across long distances without leaks. Their durability ensures that even when exposed to fertilizers and pesticides, they continue to perform without deterioration. The low cost of PVC Pipes makes them a practical solution for large irrigation networks.

Applications of PVC Pipes in Construction

Sewer and Stormwater Systems

In municipal construction, PVC Pipes are used extensively in sewer lines and stormwater management systems. Their ability to withstand underground pressure, combined with their chemical resistance, ensures that they function effectively for decades. The lightweight nature of PVC Pipes also reduces installation costs in large infrastructure projects.

Electrical and Telecommunications Conduits

PVC Pipes are not limited to fluid transport. Their insulating properties and resistance to moisture make them excellent conduits for electrical wiring and telecommunication cables. In construction, they protect sensitive wiring from environmental damage, ensuring safety and reliability in residential, commercial, and industrial buildings.

Structural Applications

Beyond plumbing and conduits, PVC Pipes are sometimes used in lightweight structural applications, such as scaffolding, temporary frameworks, or protective casings. Their versatility allows them to adapt to both functional and creative uses in construction projects.

Advantages of Using PVC Pipes

PVC Pipes offer a combination of benefits that explain their widespread adoption. One of their primary advantages is durability. With proper installation, PVC Pipes can last more than fifty years, significantly reducing the need for replacement. Their resistance to corrosion, scaling, and microbial growth ensures long-term performance in diverse environments.

Affordability is another major benefit. Compared to alternatives such as copper or steel, PVC Pipes are much cheaper to produce, transport, and install. This cost-effectiveness makes them suitable for both small-scale projects and large infrastructure developments.

Hydraulic efficiency is a further strength. The smooth surface of PVC Pipes ensures steady flow, reducing the energy required for pumping in pressurized systems. For both households and municipalities, this translates into energy savings and better system performance.

Environmental sustainability also plays a role. PVC Pipes are recyclable, and their long service life reduces the frequency of replacements, conserving resources. Additionally, their lightweight nature reduces the carbon footprint associated with transportation.

Challenges and Limitations of PVC Pipes

Despite their many benefits, PVC Pipes do have limitations. One of the primary concerns is temperature sensitivity. PVC is not suitable for transporting hot water over long periods, as prolonged heat exposure can cause deformation or reduced strength. In such cases, CPVC (chlorinated polyvinyl chloride) is a better alternative.

Another challenge is vulnerability to ultraviolet (UV) radiation. Prolonged exposure to direct sunlight can degrade PVC Pipes, causing brittleness over time. This limitation can be addressed by burying pipes underground, using protective coatings, or selecting UV-stabilized materials.

Finally, installation practices play a crucial role in performance. Poor joining techniques, inadequate bedding in underground installations, or failure to follow standards can compromise the longevity of PVC systems. Proper training and adherence to guidelines are essential for ensuring their effectiveness.

Lifecycle and Maintenance Considerations

PVC Pipes are celebrated for their low maintenance requirements. Once installed correctly, they require little intervention beyond occasional inspections. Leaks, if they occur, can be quickly repaired using simple fittings or solvent cement, making maintenance straightforward and cost-effective.

The lifecycle of PVC Pipes demonstrates excellent value. Their low initial cost, combined with decades of reliable service, makes them one of the most economical choices for plumbing and construction. When they do reach the end of their lifecycle, recycling options ensure that they do not contribute significantly to waste.

Conclusion

PVC Pipes have established themselves as one of the most versatile and reliable solutions in plumbing and construction. Their adaptability across residential, agricultural, industrial, and municipal applications demonstrates their importance in modern infrastructure. With advantages such as durability, affordability, hydraulic efficiency, and environmental sustainability, they continue to dominate global markets.

While challenges such as temperature sensitivity and UV vulnerability exist, these limitations can be managed through thoughtful design, proper material selection, and adherence to installation standards. For homeowners, contractors, and municipalities alike, PVC Pipes represent a cost-effective, durable, and environmentally responsible choice that meets the demands of modern systems.

FAQ

What makes PVC Pipes suitable for plumbing and construction?

Their durability, resistance to corrosion, affordability, and adaptability make them ideal for a wide range of applications.

Can PVC Pipes be used for hot water systems?

No, PVC Pipes are not recommended for hot water. CPVC is a better alternative for high-temperature applications.

How long do PVC Pipes last?

With proper installation, they can last fifty years or more.

Are PVC Pipes safe for drinking water?

Yes, certified PVC Pipes are safe for potable water applications and do not affect water quality.

What are common uses of PVC Pipes in construction?

They are used in water supply, drainage, sewage systems, electrical conduits, and stormwater management.

Do PVC Pipes require a lot of maintenance?

No, they require minimal maintenance, with occasional inspections and simple repairs if needed.

Are PVC Pipes environmentally friendly?

Yes, they are recyclable and their long service life reduces resource consumption and waste.

Can PVC Pipes withstand outdoor exposure?

They are vulnerable to UV radiation, so protective coatings or burial are recommended for outdoor use.

How do PVC Pipes compare to metal pipes?

They are lighter, cheaper, resistant to corrosion, and easier to install compared to metal pipes.

Why are PVC Pipes widely used in agriculture?

Because they are cost-effective, durable, and resistant to chemicals, making them ideal for irrigation systems.