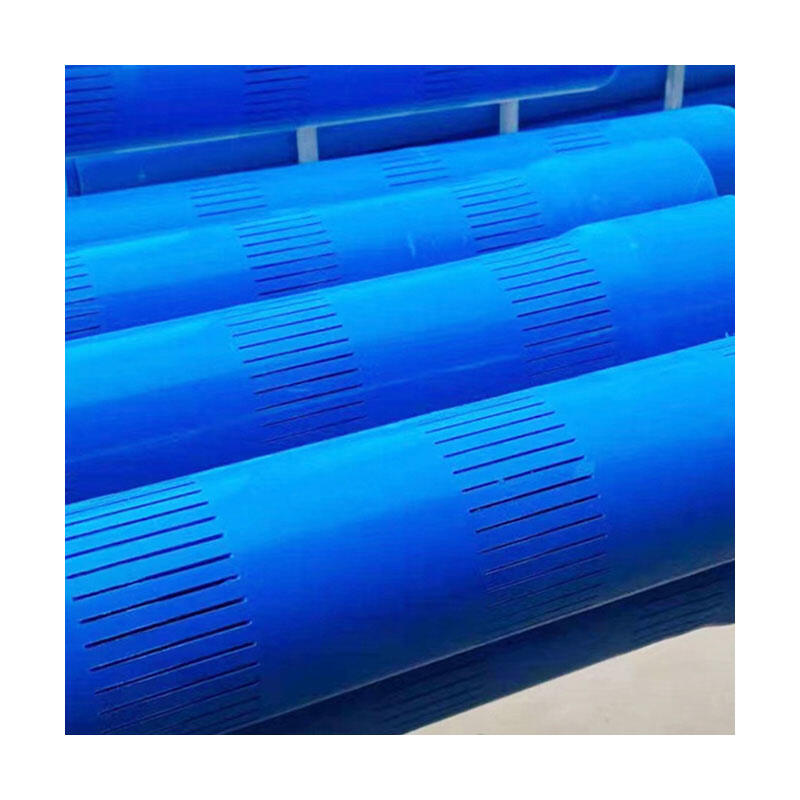

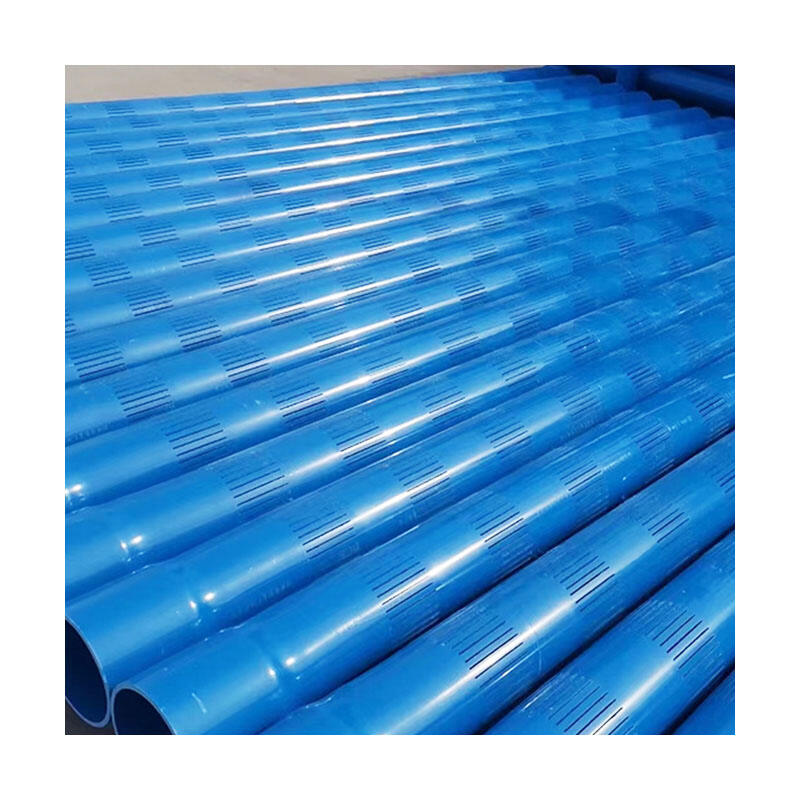

tubus involucrum PVC pro fonti aquae

Tubus crustae PVC pro puteo aquae repraesentat progressum revolutionarium in technologia construendi putorum aquae, praebens protectionem superiorem et actuatiores pro systematibus extractionis aquae domesticis, commercialibus et industrialibus. Hoc systema tuborum specializatum est pars structuralis prima quae interiorem puteorum aquae vestit, creans canalem tutum pro fluxu aquae dum contaminatio prohibetur et integritas putei per totam vitae operativam servatur. Tubus crustae PVC pro puteo aquae ex materia polivinilichloridi altissimae qualitatis fabricatur, qui rigorosos processus controlis qualitatis pertransit ut ducabilitas optima et fides certa firmetur. Functiones principales tubi crustae PVC pro puteo aquae continent subsidium structurale praebens ut ruina putei prohibeatur, zonas aquiferas diversas separando ne contaminatio mutua eveniat, extractionem aquae efficientem faciliant, et protegant adversus contaminantes externos sicut polluentes superficiales, sedimenta, et bacterias noxias. Caracteres technologici tubi crustae PVC pro puteo aquae continent formulationem polymerorum progressam quae corrosioni chemicae restat, systemata filetationis precise constructa ad nexiones tutas, crassitudinem parietis uniformem pro distributione constanti fortitudinis, et tractatus speciales superficiei qui damna frictionis durante operationibus pumpandi aquam minuunt. Applicationes tubi crustae PVC pro puteo aquae patet per sectores diversos, inclusis systematibus supplys aquae domesticis, retebus irrigationis agriculturalibus, infrastructura distributionis aquae municipalis, necessitatibus aquae pro processibus industrialibus, et installationibus aditus aquae in casibus emergentiae. Systemata hodierna tuborum crustae PVC pro puteo aquae elementa designis innovativa includunt, sicut dynamica fluxus optimizata, mechanismos obsignandi iunctarum melioratos, et compatibilitatem cum variis configurationibus apparatum pumpandi. Versatilitas tubi crustae PVC pro puteo aquae eum aptum reddit ad varias conditiones geologicas, a formationalibus terrae mollis usque ad substrata petrosa difficilia, firmando actuatioem reliabilem per loca installationis varia, simul efficaciam operativam et cursum pretii servant pro solutionibus supplys aquae longe duraturis.