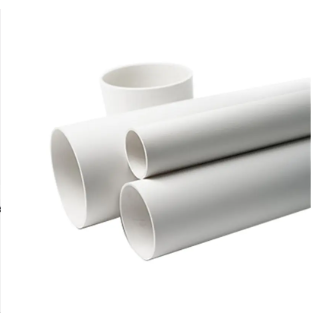

pvc dwv pipe fittings

PVC DWV pipe fittings represent a cornerstone of modern drainage, waste, and vent systems, delivering exceptional performance in residential, commercial, and industrial applications. These specialized fittings connect, redirect, and terminate PVC DWV pipes to create comprehensive plumbing networks that efficiently manage wastewater and provide essential ventilation. The primary functions of PVC DWV pipe fittings encompass waste removal from sinks, toilets, bathtubs, and other fixtures, while simultaneously facilitating proper ventilation to prevent sewer gas infiltration and maintain optimal drainage flow rates. Technologically, these fittings utilize advanced polyvinyl chloride compounds engineered specifically for drain-waste-vent applications, featuring smooth interior surfaces that minimize friction and prevent debris accumulation. The manufacturing process incorporates precise injection molding techniques that ensure consistent wall thickness, accurate dimensions, and superior joint integrity. PVC DWV pipe fittings demonstrate remarkable chemical resistance against household cleaners, acids, and alkalis commonly encountered in drainage systems, while maintaining structural stability across wide temperature ranges. Their lightweight construction simplifies installation procedures, reducing labor costs and project timelines significantly. Applications span diverse sectors including residential housing developments, apartment complexes, office buildings, hospitals, schools, restaurants, and manufacturing facilities. These fittings accommodate various pipe sizes ranging from 1.5 inches to 8 inches in diameter, supporting both gravity-fed and pressurized drainage configurations. The versatile product line includes elbows for directional changes, tees and wyes for branch connections, couplings for pipe extensions, adapters for transitioning between different pipe materials, and specialized fittings like cleanouts and floor drains. PVC DWV pipe fittings comply with stringent industry standards including ASTM D3034, ensuring consistent quality and performance reliability across all installations.