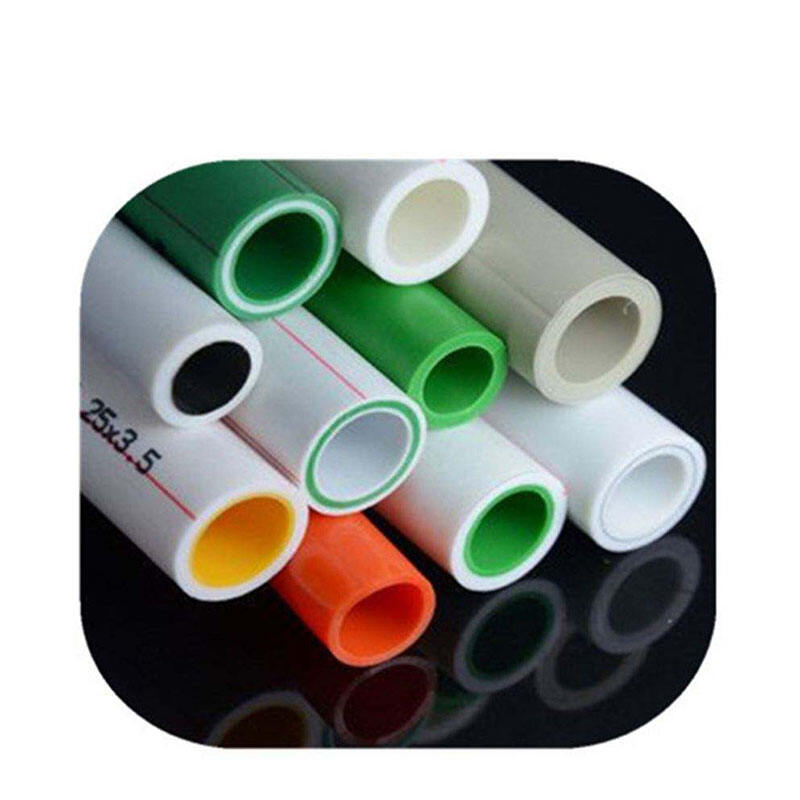

полипропилен төмс

Полипропилен хоолой нь олон төрлийн үйлдвэрлэл, орон сууцны салбарт ашиглагдах хоолойн системийн шинэчлэлтийн чухал алхам болно. Энэ термопластик хоолойн шийдэл нь гайхалтай их бат бөх чанар, химийн эсэргүүцэлтэй полимер болох полипропиленийн смолаас бүрдэнэ. Үйлдвэрлэх явцад экструзийн аргыг ашиглан цоорхойгүй, хөнгөн жинтэй, хэт өндөр температур, даралтыг тэсвэртэй даах чадвартай хоолойнуудыг үйлдвэрлэдэг. Полипропилен хоолойн систем нь уух боломжтой ус, үйлдвэрийн химийн бодис, устөрөгчийн хүчил шиг металл хоолойг задлах хортой бодисууд зэрэг янз бүрийн шингэнийг зөөхөд онцлог давуу талтай. Полипропилен хоолойн үндсэн үүрэгт шингэнийг зөөх, химийн боловсруулалт, ус түгээх, хаягдал удирдах системүүд орно. Эдгээр хоолойнууд хүнд нөхцөлд бүтцийн бүрэн бүтэн байдлыг хадгалж, бохирдлоос сэргийлэх нь чухал фармацевтик үйлдвэрлэл, хоол боловсруулалт, лабораторийн орчинд тааралдана. Технологийн онцлогт байгалийн бус бичил биетний өсөлтийг саатуулах, үрэлтийн алдагдлыг багасгах гладкий дотор гадаргуу байдаг тул урсгалын хурдны үр дүнтэй байдлыг хангаж, шингэний цэвэр байдлыг хадгална. Зохицуулсан тохиолдолд полипропиленийн молекул бүтэц нь стрессын трещины эсэргүүцэл, дулааны өргөтгөл, хэт ягаан туяаны нөлөөллөөс сайн хамгаалалт үзүүлдэг. Хөгжилтэй үйлдвэрлэх технологи нь хоолойн урт дагуу хэмжээсийн нарийвчлал, ханын зузааны нэгэн төрлийг хангана. Полипропилен хоолойн хэрэглээ нь хотын усны системээс эхлээд химийн боловсруулалтын үйлдвэр хүртэл олон салбарт түгээнэ. Орон сууцны суурилуулалт материал нь хортой бус чанар, тунамал хуримтлагдахаас тэсвэртэй байдлаар давуу талтай. Коммерцийн барилга эдгээр хоолойг HVAC систем, шахсан агаарын шугам, тусгай химийн боловсруулалтад ашигладаг. Үйлдвэрийн газрууд энэ хоолойг идэвхитэй химийн бодис зөөх, өндөр температурт ажиллах, идэвхитэй хаягдал урсгалд ашигладаг. Энэ олон талт чанар нь байгалийн бус бодис, пестицидэд тэсвэртэй учраас удаан хугацааны найдвартай байдлыг хангасан хөдөө аж ахуйн тэжээлийн системд хүртэл хүрнэ. Далайн хэрэглээнд энэ нь давсны усанд сайн тэсвэртэй байдлаар давуу талтай бөгөөд уурхай ажиллагаанд полипропилен хоолойн системийн зүйрүүлэх боломжгүй эсэргүүцэл, мөргөлдөөний бат бөх чанарыг үнэлдэг.