хөршний үндэс олгоход ашиглагддаг PVC хавтангаар бусад цолын цагаан шошго

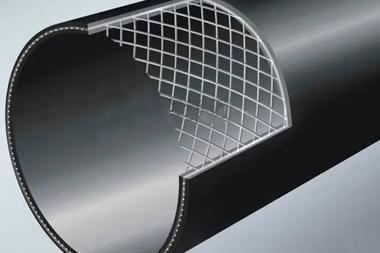

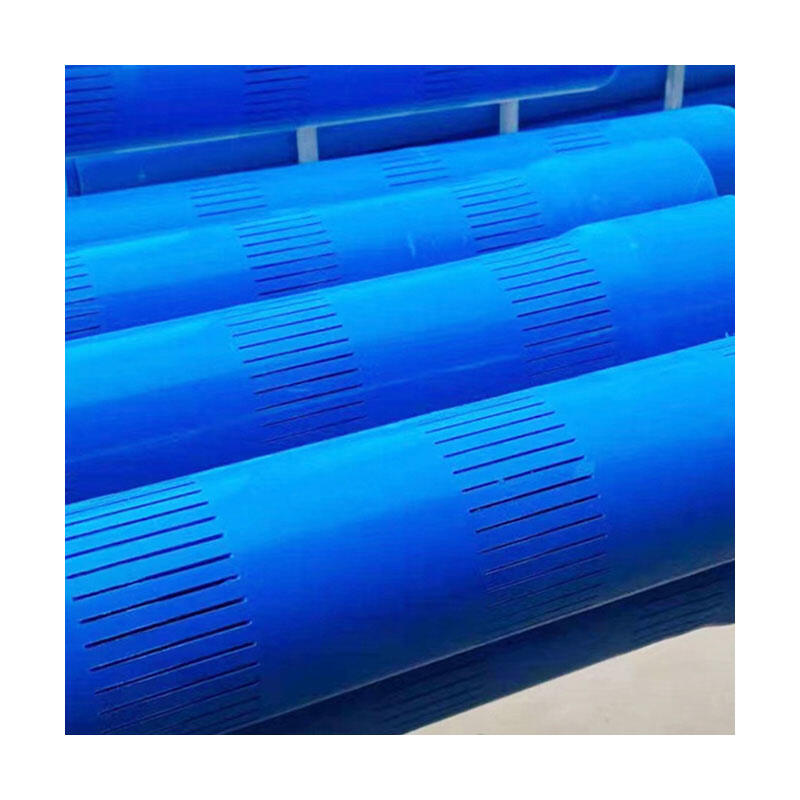

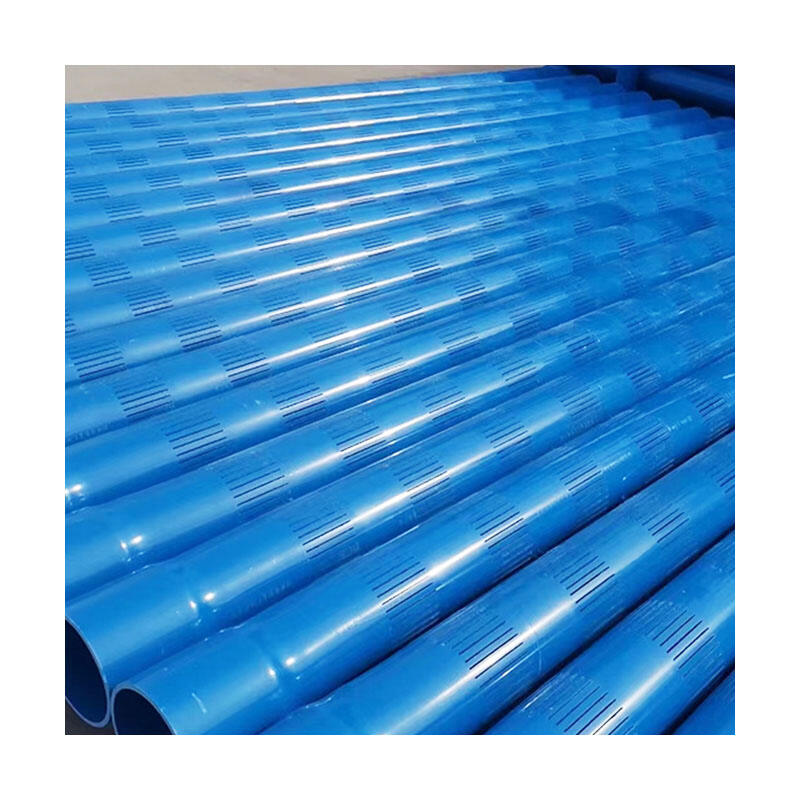

Ухлах тусгалын PVC хальсны сүлжээний хоолой нь орчин үеийн ус шахах, газрын инженерийн технологийн хэрэглээнд хувьсгалт шийдэл болдог. Энэ тусгай зориулалтын ухлагч хэрэгсэл нь поливинил хлоридын бат бөх байдал, нарийвчлалтай инженерийн шигшүүрийн чадавхийг хослуулан янз бүрийн доторх давхаргад агуу үр дүн үзүүлдэг. Ухлах тусгалын PVC хальсны сүлжээний хоолой нь газрын доорх ус шахах, орчны мониторинг, хөрсний тогтворжилт зэрэг олон чухал үүргийг гүйцэтгэдэг. Үндсэн технологийн онцлогуудад исэлдэхээс хамгаалах материал, урсгалыг сайжруулах нүхний тохируулга, стандарт хэмжээсийн дагуу үйлдвэрлэгдсэн байдлаас үүдэлтэй нийцэлтэй байдаг. Сүлжээний хоолойн шинэлэг загвар нь элс, бохирдлыг нэвтрэхээс сэргийлж, усны урсгалыг хамгийн ихээр нэмэгдүүлэх зориулалттай тасралтгүй нүхтэйгээр хийгдсэн. Үйлдвэрлэлийн явцад өндөр чанартай PVC материалыг ашиглан газрын доорх том даралт, температурын өөрчлөлтөнд тэсвэртэй байдлыг хангана. Ухлах тусгалын PVC хальсны сүлжээний хоолой нь урсгалын чадавхийг хадгалах, жижиг хэсгүүдийг барихын хооронд тэнцвэрийг оновчтойгоор тооцсон нүхний хэмжээгээр шүүх үр ашгийг хамгийн их болгодог. Хэрэглээ нь орон сууцны усны тусгал, хөдөө аж ахуйн усалгааны систем, аж үйлдвэрийн газрын доорх усны хяналт, орчны цэвэрлэлтийн төслүүдэд хүртэл хамаарна. Суурилуулах ажиллагаанд стандарт ухлагч аргачлалыг ашигладаг бөгөөд сүлжээний байршил, чулуун дүүргэвчийн суурилуулалтанд тусгай анхаарал хандуулдаг. Хоолойн хөнгөн жин нь тээврийн зардлыг бууруулах, суурилуулах үед гаргалтыг хялбаршуулдаг. Чанарын хяналтын арга хэмжээнүүд нь PVC хальсны сүлжээний хоолой бүр хэмжээсийн нарийвчлал, материал дахь найрлагаар нь индустрийн журамд нийцэж байгаа эсэхийг хангана. Ажиллагааны даралт, урсгалын онцлог, урт хугацааны тэсвэрт чадлыг шалгах тестүүдээр үр дүнг баталгаажуулдаг. Орчны хувьд дахин боловсруулж болох материал, устөрөгчийн хий гарц багатай байх нь уламжлалт металлын хувилбартай харьцуулахад давуу тал юм. Системийн модуль загвар нь төслийн шаардлага, геологийн нөхцөлд нийцсэн захидал буюу захидмал хэлбэртэйгээр тохируулах боломжийг олгодог.