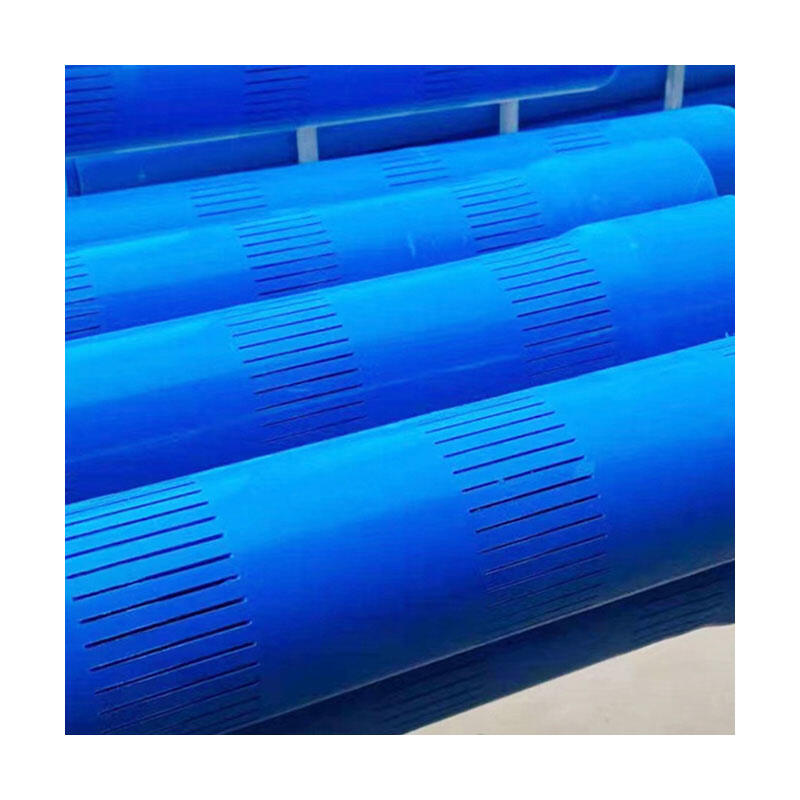

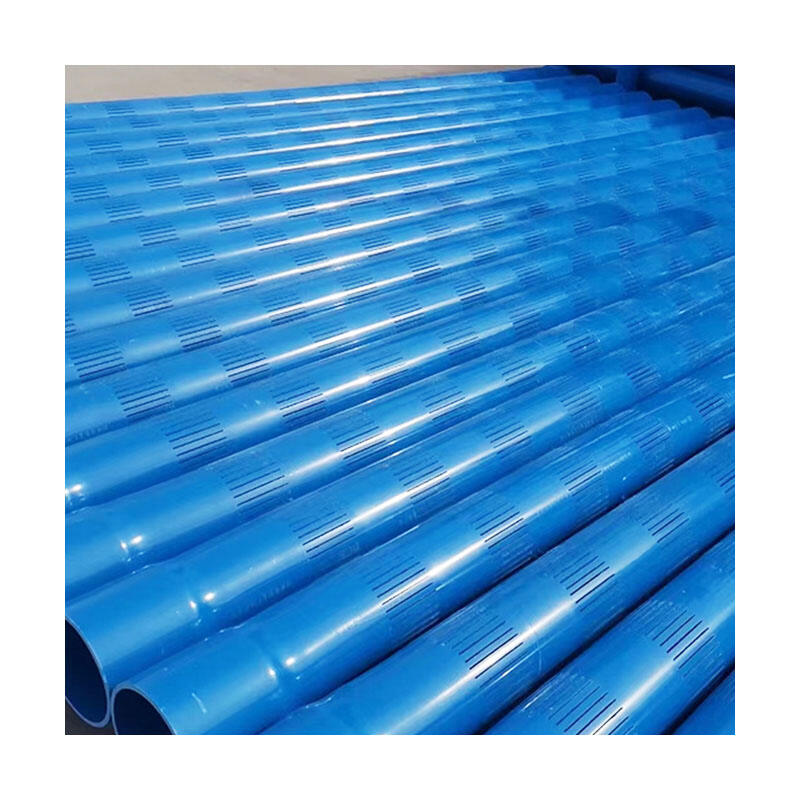

pvc pipe for well casing installation

PVC pipe for well casing installation represents a revolutionary advancement in water well construction technology, providing superior protection and longevity for groundwater extraction systems. This specialized piping solution serves as the primary barrier between the wellbore and surrounding soil formations, ensuring clean water delivery while maintaining structural integrity throughout decades of operation. The main functions of PVC pipe for well casing installation encompass wellbore stabilization, contamination prevention, and efficient water flow management. These pipes create a sealed conduit that prevents loose soil, rocks, and surface contaminants from entering the water supply, while simultaneously maintaining the well's structural stability against ground pressure and settling. Technological features of PVC pipe for well casing installation include exceptional chemical resistance, UV stabilization, and precise dimensional accuracy that ensures perfect fitting during installation. The manufacturing process incorporates advanced polymer science, resulting in pipes that resist corrosion from acidic groundwater conditions and maintain their structural properties under varying temperature fluctuations. The smooth interior surface of PVC pipe for well casing installation minimizes friction losses, allowing for maximum water flow rates with reduced pumping energy requirements. Applications for this versatile piping system extend across residential water wells, agricultural irrigation systems, municipal water supply projects, and industrial groundwater extraction operations. The lightweight nature of PVC pipe for well casing installation significantly reduces transportation costs and simplifies handling procedures during installation, while its flexibility allows for accommodation of minor ground shifts without compromising system integrity. Environmental considerations make PVC pipe for well casing installation an increasingly popular choice among contractors and well owners, as these pipes contain no heavy metals and can be recycled at the end of their service life. The joining methods available for PVC pipe for well casing installation include solvent welding, threaded connections, and specialized well casing couplers, providing installation flexibility for various project requirements and soil conditions.