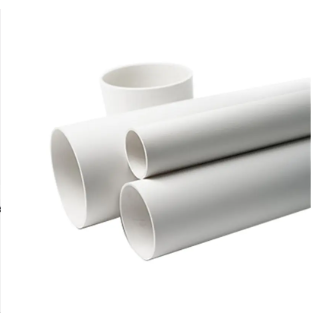

Superior Corrosion Resistance and Chemical Stability

The upvc pipe for ventilation demonstrates exceptional resistance to corrosion and chemical attack, making it the ideal choice for demanding ventilation applications across various industries and environments. Unlike traditional metal ductwork that succumbs to rust, oxidation, and chemical degradation over time, upvc pipe for ventilation maintains its structural integrity and performance characteristics even when exposed to aggressive chemicals, high humidity, and corrosive airborne contaminants. This remarkable resistance stems from the material's molecular structure, which remains stable when exposed to acids, alkalis, salts, and organic compounds commonly found in industrial and commercial ventilation systems. The upvc pipe for ventilation technology ensures that air quality remains uncompromised throughout the system's operational lifetime, as the material does not release particles or contaminants into the airstream. This chemical stability proves particularly valuable in healthcare facilities, laboratories, food processing plants, and manufacturing environments where air purity is critical. The non-reactive nature of upvc pipe for ventilation prevents the formation of harmful compounds that could compromise indoor air quality or create health hazards for building occupants. Property owners benefit from significantly reduced maintenance costs and extended system lifecycles, as the upvc pipe for ventilation requires no protective coatings, treatments, or regular replacement due to corrosion damage. This durability advantage becomes even more pronounced in coastal environments where salt air accelerates metal corrosion, or in industrial settings where chemical vapors would quickly degrade conventional ductwork materials. The upvc pipe for ventilation maintains consistent performance characteristics throughout its service life, ensuring reliable air movement and system efficiency without the gradual degradation associated with corroding metal systems. Additionally, the material's resistance to biological growth prevents the accumulation of mold, bacteria, and other microorganisms that can thrive in moist environments within traditional ductwork, contributing to healthier indoor environments and reduced cleaning requirements.