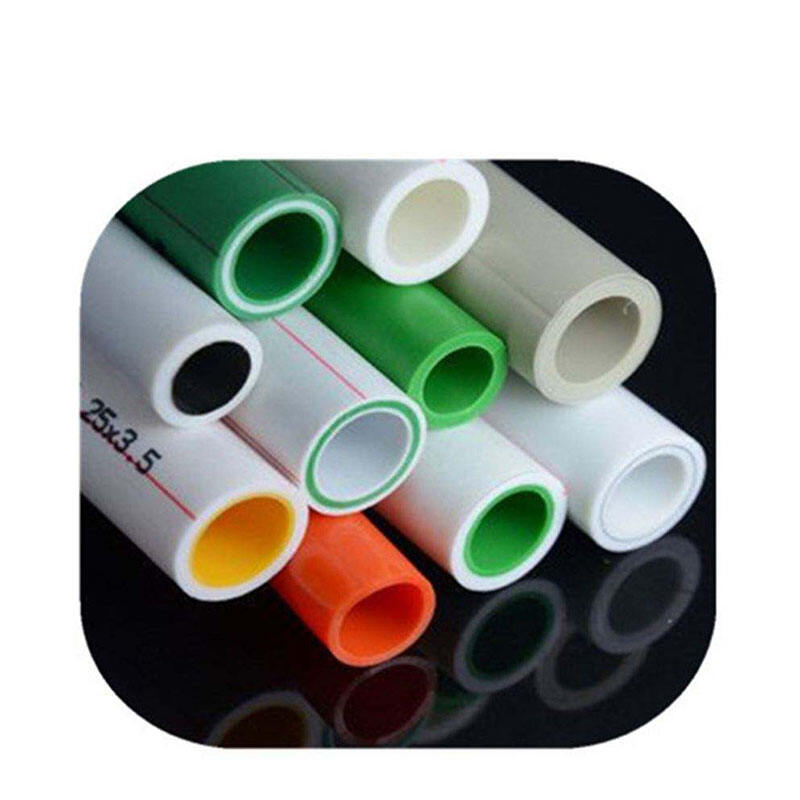

tubi polypropylene pro aqua calida

Tubuli ex polyporopilene pro aqua calida repraesentant progressum revolutionarium in systematibus sanitariis modernis, specialiter ad applications alti gradus temperaturae tractandas cum fidelitate et praestantia exceptionali comparatis. Hi tubuli speciales ex materiis polyporopilenis gradus alti fabricantur quae processibus polymerorum provectis subiciuntur, ut solutio ductilis creetur quae continuo usque ad 95 gradus Celsius grados ferre possit, idoneam pro systematibus distributionis aquae calidae domesticis et commercialibus reddens. Functiones principales tubulorum ex polyporopileno pro aqua calida continent distributionem thermalem efficientem, integritatem qualitatis aquae servandam, et stabilitatem structuralem diuturnam sub conditionibus pressionis variantibus praebendam. Hi tubuli constructionem multistratam habent, quae materiales armaturae, plerumque alluminii vel vitrifibrae, inter strata interna et externa ex polyporopileno includit, efformans structuram compositam quae flexibilitatem cum robore coniungit. Caracteres technologici continent superiorem dilationem thermicam regendam, quae motum tubulorum et tensionem in iuncturis durante mutationibus temperaturae minuit, et excellentem resistentiam chemicam quae degradationem ab chemicialibus tractamentis aquae et mineralibus, quae in aquis municipibus communiter inveniuntur, prohibet. Superficies interna fluxus levis proprietates servat quae frictionis damna minuunt et accumulationem crustae impediunt, pressionem aquae et velocitates fluxus per totam vitae spatium systematis constantes servantia. Applicationes tubulorum ex polyporopileno pro aqua calida patet per systemata calefactionis domesticis, distributiones aquae calidae in aedificiis commercialibus, lineas aquae industrialibus, et installationes calefactionis per planitiem radiantem. Processus installationis technicas soldandi fusionis utitur quae iuncturas continuae, sine effusione, firmiores quam ipse materialis tubulorum creant. Hi tubuli in installationibus tam apertis quam occultis durabilitatem exceptionalem demonstrant, integritatem structuralem in cavitatibus parietum, lastris concretis, et applicationibus foris servantes ubi variationes temperaturae magnae sunt. Natura levis tubulorum ex polyporopileno pro aqua calida complexitatem installationis et mercedem operariorum minuit, dum praestantiam superiorem praebet comparata systematibus ductilium metallicis quae a corrosionibus, incrustationibus, et dilationibus thermalibus pati possunt.