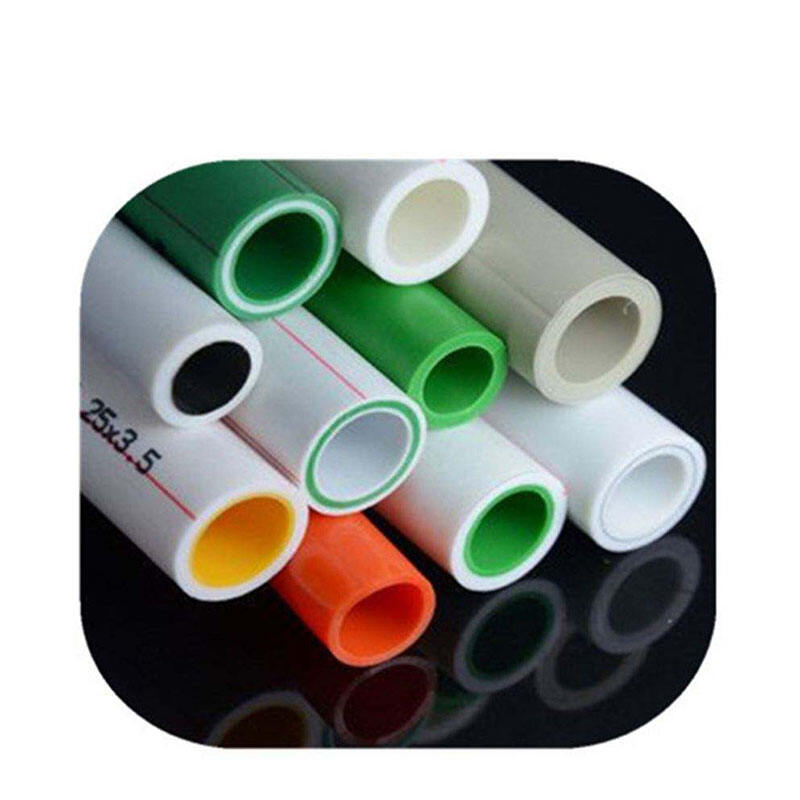

tubus plasticus pp

Tubus plasticus pp repraesentat progressum revolutionarium in solutionibus conductorum modernis, ex materialibus polypropylenis altissimae qualitatis elaboratus, qui praestationem praestantem praebet in variis applicationibus. Hoc systema conductorum innovativum vim superiorem chemicae resistentiae cum durabilitate mirabili coniungit, idoneum pro installationibus domesticis, commercialibus et industrialibus reddens. Tubus plasticus pp technologiam polymericam adhibitam habet quae constantiam crassitudinis parietum et distributionem uniformem materiae per totam structuram firmat. Processus fabricationis technicas extrusionis ultimae generationis utuntur, quae tubos continui, sine defectibus creant, extremas temperaturas ab -20°C usque ad 95°C ferre capaces. Structura molecularis tubi vim egregiam adversus acida, alkalibusa et varios solutos organicos praebet, fidentiam diuturnam in locis difficilibus garantizans. Praecipua elementa technica includunt systemata iuncturarum exacte constructa quae nexibus sine effusione certificant, superficies internas levigatas quae frictiones minuunt, et constructionem leviorem quae procedurae installationis facillimas reddit. Tubus plasticus pp compunda cum stabilitate UV incorporata habet quae degradationem ob solem expositem prohibet, vitam operativam longius producens comparata materialibus traditionalibus. Applicationes in pluribus sectoribus patentes sunt, inter quos numerantur rete distributionis aquae, aedificia tractationis chimicarum, systemata gestionis sordium et installationes HVAC. Versatilitas tubi eum aptum reddit pro ductionibus aquae calidae et frigidae, systematibus cloacalibus, transporto chimicorum industrialium et retibus irrigationis agriculturalibus. Sustinibilitas environmentalis alterum aspectum crucialem tenet, quod tubus plasticus pp plane recyclabilis sit et per processus amico-ambiente fabricatus sit qui pedem carbonis minimificent. Proprietates materialis sine toxico tutam aquae potabilis transportationem praebent, sine sapore aut odore immutato. Cautelae qualitatis provectae in productione constantiam in mensura et pressionis gradibus garantizant, qui normis internationalibus, inter quas ISO, ASTM et DIN, satisfaciunt. Systema tuborum plasticorum pp flexibilitatem modulari designis offert, quae expansionem facilem et modificationem installationum iam existentium sine opere reconstructionis ampla permittit.