Praeventio Perdendi Completa et Integritas Systematis

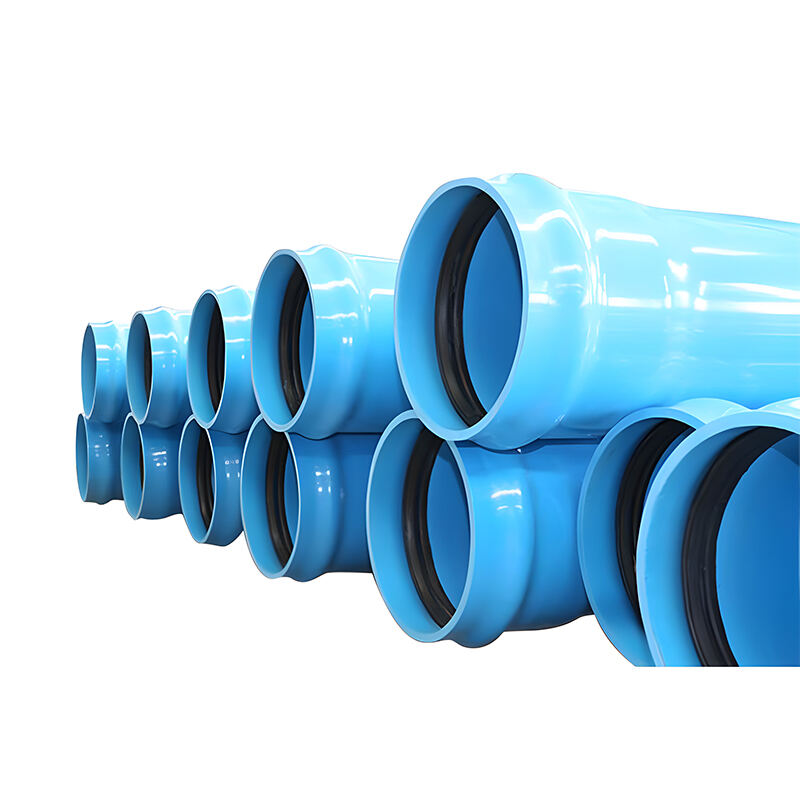

Caelatura tuborum PVC praestat inaestimabilem facultatem praeventionis effusionis, quae omnes alias iuncturas superat per creationem perfecte obsignatorum, monolitarum coniunctionum. Contrario quam iuncturae filetatae, quae dependant a signinis, vel coniunctiones mechanicae, quae gypsis utuntur, caelatae iuncturae PVC continuam materialem copulationem formant, quae omnino tollit vias effusionis possibiles. Haec fundamentalis praerogativa magni momenti est in applicationibus, ubi etiam minores effusiones gravia problemata creare possunt, sicut in systematibus aquae potabilis, ubi pericula contaminationis minimizari debent, vel in systematibus tractationis chemicorum, ubi damnum producti tam economicum quam securitatis rationes afficit. Processus caelaturae firmat nullas materias externas vel potentialia puncta defectus intra structuram iuncturae esse, creans coniunctiones quae suam integritatem obsignandi servant, sive temperaturis variantibus, sive motu terrae, sive fluctuationibus pressionis systematis. Emerserunt emolumenta environmentalia ex hac facultate praeventionis effusionis, quia systemata PVC caelata res aquarias conservant et contaminationem solois praebent, quae ex effusionibus subterraneis oriri possent. Lucrum efficaciae energeticae ex systematibus sine effusione est grande, quia machinae pompantes ad efficientiam optimam operantur, sine compensatione pro damnis systematis. Curae qualitatis fit facilis cum caelatura tuborum PVC, quia inspectio visualis durante processo refrigerandi defectus possibiles ostendit, qui integritatem iuncturae compromittere possent. Absentia materialium obsignantium consumibilium deperditionis curas tollit, quae iuncturas mechanicatas tempore vexant. Compatibilitas chemica per totam iuncturam caelatam manet constans, quia nulla materia dissimilia introducuntur quae adversis reactionibus cum fluidis transportatis affici possint. Experimenta pressionis in systematibus PVC caelatis constantissime suam facultatem designandi pressiones servandi usquequaque demonstrant, fiduciam praebentes pro applicationibus criticis. Tollere necessitudinem mendentionis periodicae pro obsignatione iuncturae magnos sumptus salvatos significat per totam vitae spatium systematis, praesertim pro rebus amplis, ubi aditus ad iuncturas humatas costosas excavationes requireret.