Үйлчилгээний амьдралын үргэлжлэх хугацааг уртасгах

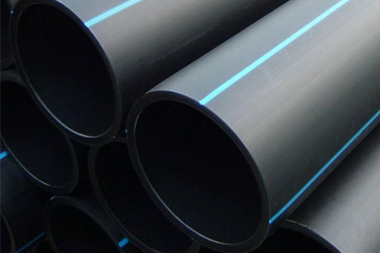

Крах хоолойн үргэлжлэх хугацааны ашиглалтын үзүүлэлт нь материалын шинжлэх ухаан болон нарийвчилсан үйлдвэрлэлийн дэвшилтэт технологийн нэгдэл бөгөөд ажиллагааны найдвартай байдлыг жилээр биш, харин аравтын тоогоор хэмждэг. Шинжилгээний лабораторийн нөхцөлд хийсэн хурдасгагдсан нас баруулах судалгаагаар тусгай орчинд 50 жилийн үйлчилгээний нөхцлийг богино хугацаанд загварчилж, материал ямар нэгэн чухал эвдэрэлгүйгээр бүтцийн чадавхыг хадгалж байгааг харуулсан. Энэхүү урт хугацааны үйлчилгээ нь хэвийн хоолойн системд цаг тухайд нь гэмтэл үүсгэдэг орчны хүчин зүйлсийг эсэргүүцэх чадвартай материал дахин давтагдашгүй тогтвортой байдлаас үүдэлтэй. Полимерийн химийн бүтцийн үр дүнтэй сайжруулалт нь дулааны цикл, химийн бодисын нөлөөлөл, механик ачаалал зэрэг нөхцөлд бусад материалыг даамжруулан сулруулдаг ч, Крах хоолойн хувьд уян хатан чанар, бат бөх чанарыг хадгалж байна. Үйлдвэрлэлийн чанарын хяналт нь тогтмол ханын зузаан, материал тараах чадварыг хангаж, доогуур чанарын бүтээгдэхүүнд ихэвчлэн гардаг сул цэгүүдийг арилгана. Талбайн суурилуулгын хяналтаас харахад зөв суурилуулсан Крах хоолойн систем нь хэд хэдэн арван жилийн тасралтгүй ажиллаж байгаа ч анхны үзүүлэлтүүдээ алдахгүйгээр хадгалж, цөөн хэмжээний засвар хийх шаардлагатай бөгөөд илүү их эвдрэл харагдахгүй байна. Урт хугацааны үйлчилгээ нь солих зардлыг бууруулснаар, системийн зогсонги байдлыг хамгийн бага болгоноор, байгууллагын менежерүүд болон хотын захиргаанд төсөвийн илүү сайн таамаглал өгч, маш их эдийн засгийн өртөгийг бий болгодог. Үргэлжлэх хугацааны ашиглалтын үзүүлэлтэд үйлдвэрлэгчийн итгэл найдварыг харуулах баталгаат хугацаа нь инфраструктурын хөрөнгө оруулалтад нэмэлт аюулгүй байдлыг хангаж, бүтээгдэхүүний урт хугацааны найдвартай байдлын талаарх хариуцлагатай хандлагаа харуулдаг. Үйлчилгээний хугацааг сунгаснаар материал хэрэглээг багасгаж, барилгын ажиллагааг бууруулж, олон удаа солих шаардлагатай тээврийн ачааллыг багасгаж, орчныг хамгаалахад хувь нэмэр болдог. Үзүүлэлтийг хянах систем нь суурилуулгын нөхцлийг бодит цагт хянах, урьдчилан сэргийлэх засварын боломжийг олгох бөгөөд урт хугацааны үйл ажиллагааны туршид системийн найдвартай байдлыг хангана. Инженерийн шинжилгээ нь Крах хоолойн суурилуулга нь бусад материалыг солих шаардлагатай болоход хэтрүүлэн найдвартай үйлчилгээ үзүүлж, эхний хөрөнгө оруулалтыг оправдан болгох, илүү дээд зэргийн инфраструктурын өртгийг нэмэгдүүлэх ач холбогдолтой мөчлөгийн зардал болон үйл ажиллагааны давуу талыг бий болгодог.