зочид системд ашиглагдах PE шугам

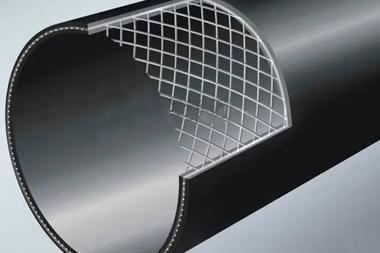

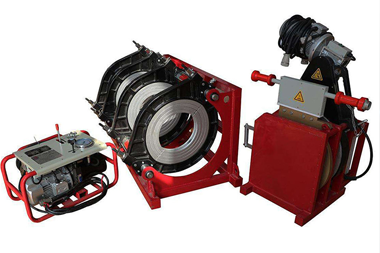

Бохир усны системд зориулсан PE хоолой нь бохир усны менежментийн суурин дэд бүтцийн шинэлэг ахиц юм. Энэ нь хот ба аймаг, мөн үйлдвэрлэлийн салбарт орчин үеийн цэвэршилийн шаардлагыг хангах найдвартай шийдэл санал болгодог. Полиэтилен хоолойн системүүд нь онцгой үнэнч чанар, ажиллах чадвараараа бохир усны тээврийг хувиргасан. Эдгээр тусгайлан зориулсан замууд нь хотын бохир ус, үйлдвэрийн хаягдал, мөн борооны усыг маш үр дүнтэй зөөдөг. Бохир усны системд зориулсан PE хоолой нь газрын доорх суурилуулалт, хатуу орчин үеийн нөхцөл байдлыг зорилго болгон үйлдвэрлэсэн хичээлтэй полиэтилен материалыг агуулдаг. Үндсэн үүргүүд нь орон сууцны бүс нутгаас цэвэрлэх төвүүд рүү шинэ бохир ус тээвэрлэх, үйлдвэрийн хаягдлыг удирдах, мөн хүн амын нягтарсан газраас борооны усыг чиглүүлэх явдал юм. Бохир усны системд зориулсан PE хоолойн технологийн онцлогт шингэний тээврийн үед бөглөрөл үүсгэхээс сэргийлж, үрэлтийн алдагдлыг бууруулах зориулалттай гладкийн гадаргуу орно. Хөгжим хөгжилттэй үйлдвэрлэх арга замууд нь хоолойн сүлжээн даяар тогтмол ханын зузаан, давуу чанартай холболтыг хангана. Эдгээр системүүд нь бохир усны урсгалд ердийн тохиолддог хүчил, шүлт, мөн органик нэгдлүүдэд тэсвэртэй байдаг. Полиэтилен материал нь газрын хөдөлгөөн, газар хөдлөлт, хөлдөөх-хайлах үеийг давин чангарч, трещин, эвдрэл үүсгэхгүйгээр бохир усны системд зориулсан PE хоолойн уян хатан чанарыг хангана. Суурижуулах хэрэглээ нь орон сууцны бүс, худалдааны төслүүд, үйлдвэрийн комплекс, хотын дэд бүтцийн төслүүдэд хүртэл тархана. Бохир усны системд зориулсан PE хоолой нь гравитацын цуглуулалтын сүлжээ, даралттай бохир усны систем, мөн хүчний гол хоолойн хэрэглээг дэмждэг. Орчин үеийн цахилгаан хайлуурын техник нь устгал, гадагшлан орох асуудлыг шийдвэрлэхгүй байгаа уламжлалт хоолойн материалд гардаг шугамын холболтыг бүтнээр нь зайлуулдаг. Инженерүүд, гэрээт ажилтангуудын урт хугацааны үйлчилгээг хайж буй экологийн үр ашигтай байдлын хувьд бохир усны системд зориулсан PE хоолой илүү их түгэв. Материалын найрлага нь үйлчилгээний амьдралын төгсгөлд бүрэн дахин боловсруулах боломжийг олгох бөгөөд инфраструктурын хөгжилд дугуй эдийн засгийн зарчмыг дэмждэг.