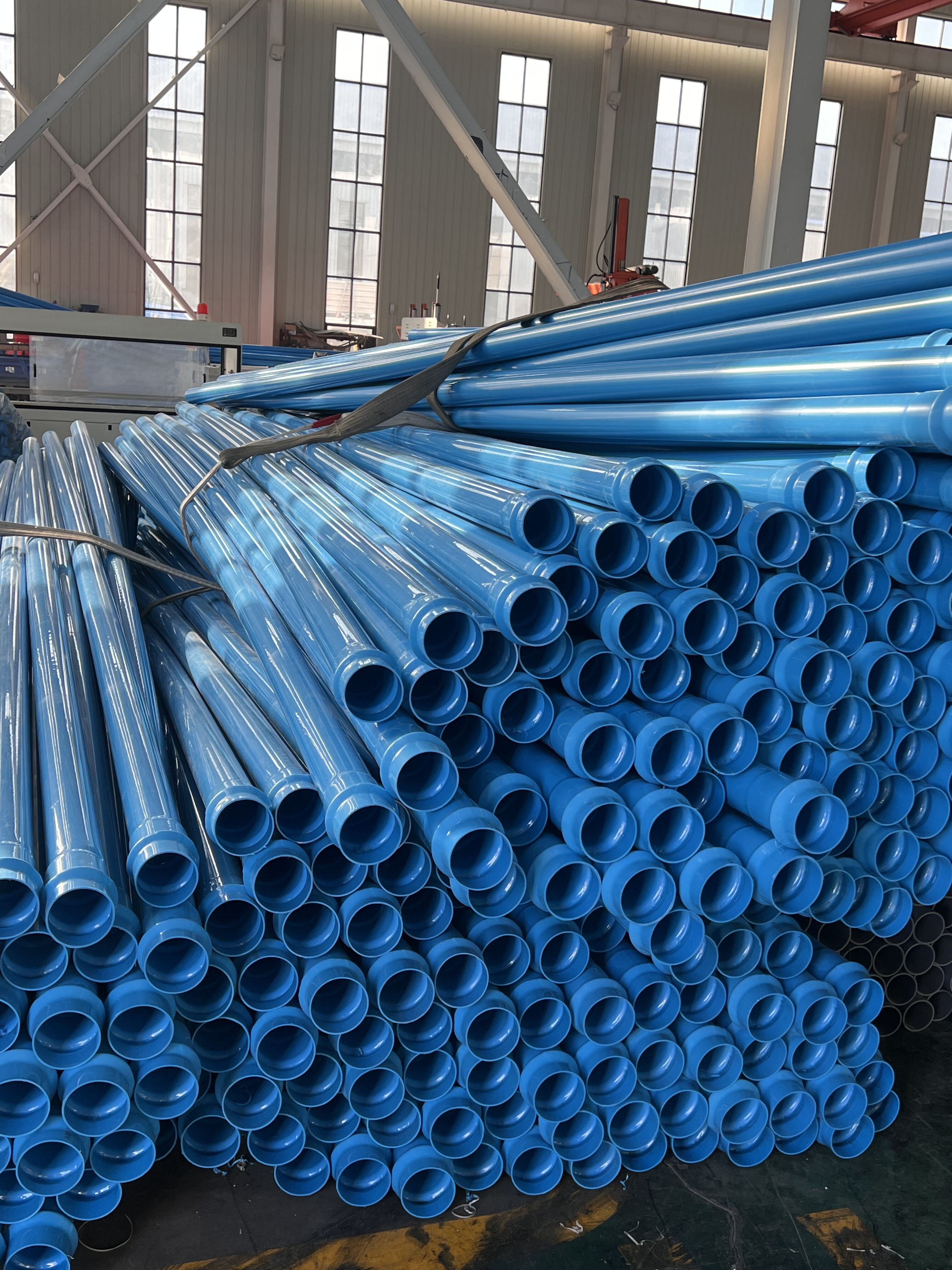

Redefining Pipeline Strength: PVC-O, Defining the Future of Water Conveyance with Molecular Orientation Technology

Within the hidden veins of infrastructure, an evolution in pipeline performance is underway. PVC-O (Biaxially Oriented Polyvinyl Chloride) pipe, through innovation rooted deeply in materials science, is pushing beyond the performance limits of traditional piping. It is not merely an upgrade of ordinary plastic pipe but represents an essential leap from "durable" to "exceptional" achieved by restructuring the polymer's microscopic world, making it a benchmark for high performance in water conveyance.

I. Core Principle: An Orderly Revolution Starting at the Molecular Scale

The excellence of PVC-O is founded on its core "biaxial orientation" manufacturing process. This involves the precisely controlled biaxial stretching of a standard PVC-U pipe blank, forcing the polymer chains to become highly oriented and crystallized along both the axial and radial dimensions.

• A Quantum Leap in Performance: This process is akin to combing and weaving a tangled mass into a strong net. The transition from molecular disorder to high order significantly increases the material's structural density and integrity. The result is a revolutionary enhancement in mechanical properties—particularly strength and toughness—while inheriting PVC's advantages of corrosion resistance, excellent hydraulic performance, and hygiene.

II. Exceptional Characteristics: Five Core Advantages Born from Structural Order

The reorganization at the molecular level translates directly into practical advantages that capture the engineering community's attention:

1. Exceptional Strength and Toughness: Its impact strength and fatigue resistance are outstanding, enabling effective resistance to high pressure, water hammer, and external loads. Its performance remains excellent even in low-temperature environments,彻底颠覆ing the traditional perception of plastic pipes as "brittle."

2. Significant Lightweighting: At equivalent pressure ratings, its wall thickness can be approximately 30%-50% thinner than traditional PVC-U pipes. The substantial reduction in weight leads to comprehensive improvements in transportation, handling, and installation efficiency, significantly saving construction costs and energy consumption.

3. Superior Crack Resistance: The reinforced molecular structure effectively inhibits the initiation and propagation of cracks, offering top-tier resistance against the hazardous "rapid crack propagation" in pipeline systems, ensuring long-term operational safety and reliability.

4. Excellent Hydraulic Characteristics: A thinner wall means a larger effective internal diameter. Combined with its inherently smooth inner wall, this significantly reduces fluid flow friction, improves conveyance efficiency, and delivers clear long-term energy savings.

5. Full Lifecycle Value and Environmental Profile: High strength contributes to a longer service life and greater safety margin. Its low carbon footprint across the entire lifecycle—from production and transportation to operation and maintenance—along with its recyclability, aligns perfectly with green and sustainable development principles.

III. Application Outlook: The Ideal Choice Driving Upgrades in Key Sectors

With this combination of advantages, PVC-O pipe has become the preferred solution for several critical application scenarios:

• Municipal Water Supply Mains: High pressure rating, low leakage, and long service life make it a reliable safeguard for upgrading urban water supply safety and efficiency.

• Large-Scale Water Conservancy and Agricultural Irrigation: Lightweight for easy large-area installation, with excellent corrosion resistance suitable for various complex environments.

• Industrial and Mining Water Conveyance: Outstanding impact and fatigue resistance capable of withstanding demanding operational challenges.

• Trenchless Pipeline Rehabilitation: Its high toughness and relatively smaller outer diameter make it an ideal lining material for rehabilitation techniques like slip-lining.

Conclusion

PVC-O pipe is an outstanding embodiment of materials science wisdom in the field of engineering. Through the philosophy of "thinner, lighter, stronger," it pushes the performance ceiling of plastic piping to new heights. This is not merely a product iteration but represents a forward-thinking approach that uses technological innovation to enhance infrastructure quality. In addressing the shared challenges of global water resource management, system efficiency improvement, and sustainable development, PVC-O is becoming a crucial component in building the water conveyance systems for the next century, thanks to its robust and reliable performance.