abrasionresistant dredging pipeline for harsh environments

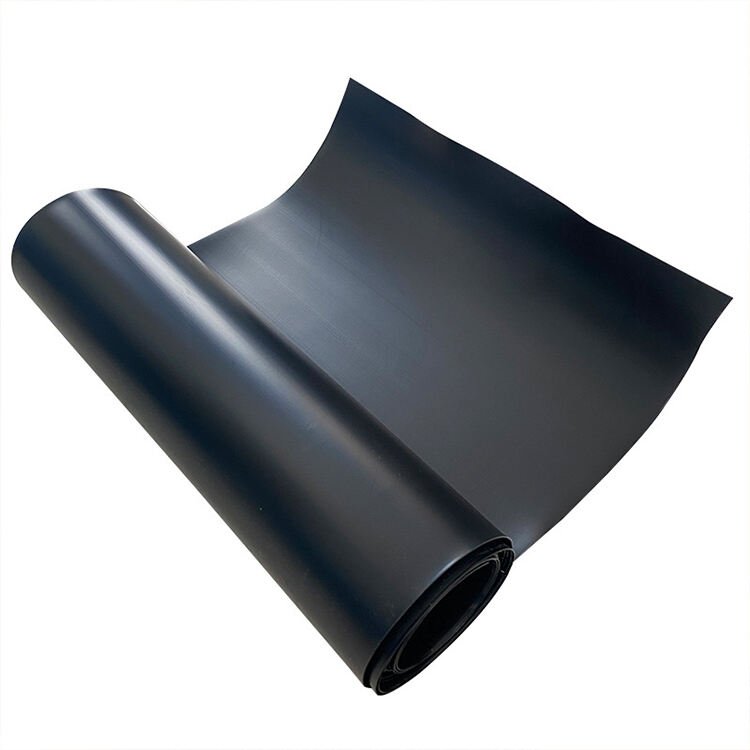

The abrasionresistant dredging pipeline for harsh environments represents a critical engineering solution designed to withstand the demanding conditions of marine construction, mining operations, and industrial dredging projects. This specialized pipeline system delivers exceptional durability through advanced material engineering and robust construction methodologies that address the unique challenges faced in extreme operational conditions. The primary function of this abrasionresistant dredging pipeline for harsh environments centers on transporting abrasive materials, including sand, gravel, rocks, and sediment mixtures across extended distances while maintaining structural integrity under severe stress conditions. These pipelines feature sophisticated wear-resistant internal linings that protect against erosion caused by high-velocity particle flow, ensuring consistent performance throughout extended operational periods. The technological architecture incorporates multi-layer construction with specialized polymer coatings and reinforced steel frameworks that provide superior resistance to impact damage, chemical corrosion, and thermal expansion. Advanced joint systems enable flexible installation configurations while maintaining leak-proof connections that withstand dynamic loading conditions typical in marine environments. The abrasionresistant dredging pipeline for harsh environments utilizes innovative manufacturing processes that optimize material density and surface hardness, creating exceptional resistance to wear patterns commonly encountered during continuous operation. Applications span across diverse industries including port development, beach nourishment projects, mining extraction operations, and environmental remediation efforts. These pipelines prove essential for offshore drilling platforms, land reclamation projects, and underwater excavation operations where conventional piping systems fail due to excessive wear rates. The engineering design accommodates varying pressure requirements, flow velocities, and material compositions while ensuring operational reliability in challenging weather conditions, extreme temperatures, and corrosive marine atmospheres that characterize harsh environmental applications.