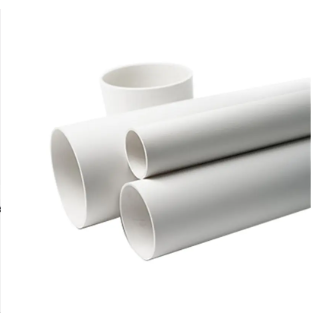

upvc pipe

UPVC pipe, short for Unplasticized Polyvinyl Chloride pipe, represents a revolutionary advancement in modern plumbing and construction infrastructure. This rigid plastic piping system has transformed how we approach water distribution, sewage management, and various industrial applications. Unlike traditional materials such as metal or concrete pipes, UPVC pipe offers superior performance characteristics that make it the preferred choice for residential, commercial, and industrial projects worldwide. The manufacturing process involves creating pipes from polyvinyl chloride resin without adding plasticizers, resulting in a rigid, durable product that maintains its structural integrity over decades of service. UPVC pipe systems excel in transporting potable water, handling wastewater, managing stormwater drainage, and facilitating chemical transportation in industrial settings. The technological features of UPVC pipe include exceptional chemical resistance, smooth internal surfaces that prevent sediment buildup, and lightweight construction that simplifies installation procedures. These pipes demonstrate remarkable resistance to corrosion, scaling, and biological growth, ensuring consistent flow rates and water quality throughout their operational lifespan. The material composition provides excellent electrical insulation properties, making UPVC pipe suitable for applications where electrical conductivity must be avoided. Modern manufacturing techniques ensure precise dimensional accuracy and consistent wall thickness, enabling reliable joint connections and system integrity. UPVC pipe applications span across municipal water supply networks, residential plumbing systems, irrigation projects, industrial process piping, and underground utility installations. The versatility of UPVC pipe makes it indispensable for swimming pool circulation, chemical processing facilities, and agricultural water management systems. Environmental considerations favor UPVC pipe selection due to its recyclability and reduced carbon footprint compared to metal alternatives.