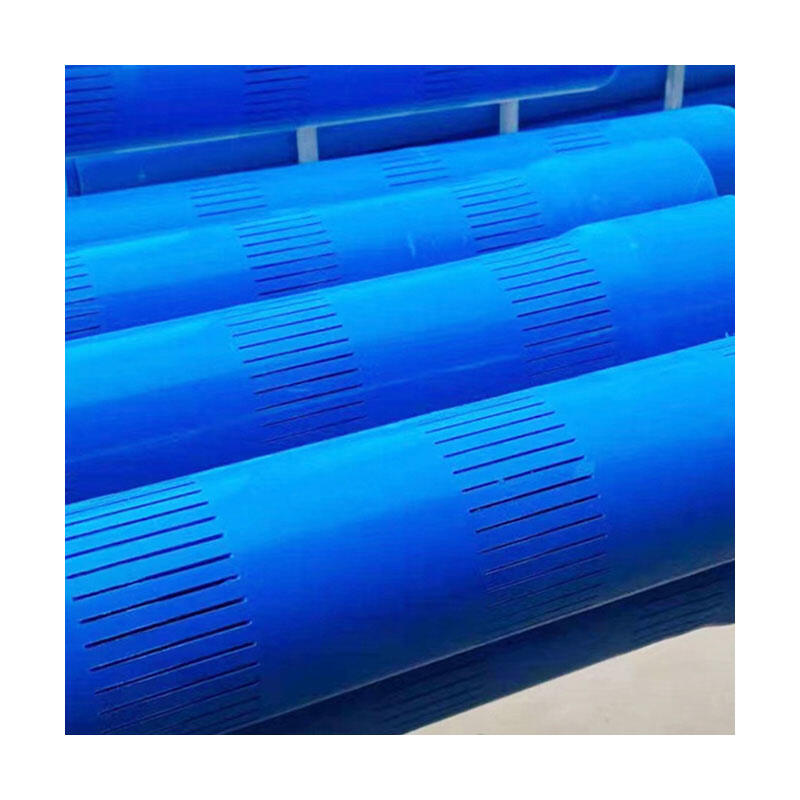

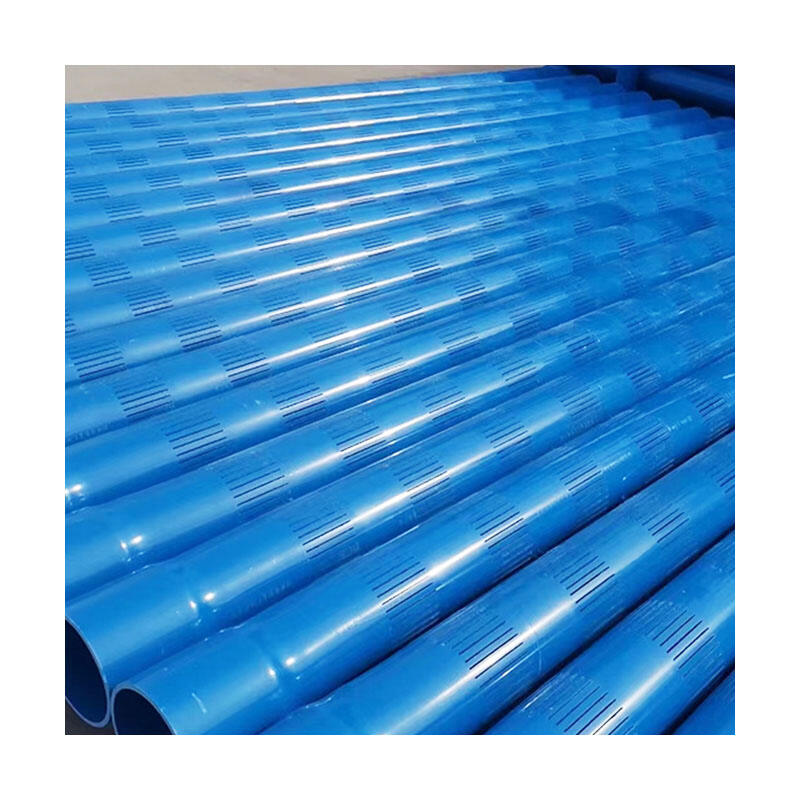

cassis pvc completa ad mensuram

Tubus PVC personalisatus plenus magnitudinis repraesentat progressum revolutionarium in technologia ductuum, specifice excogitatam ad variarum applicationum industriales et commerciales exigentias satisfaciendum. Haec solutio ductilis specialis durabilitatem intrinsecam polychloridi vinylici combinit cum technicis fabricandi praecisis ad praestantiam superiorem in multis sectoribus praebendam. Tubus PVC personalisatus plenus magnitudinis praecipue fungitur systemate teguminario protectorio pro variis lineis utilitatum, cavis telecommunicationum, et retibus distributionis aquae. Caracteres technologici eius principales includunt specificata grossitiae parietum auctas, configurationes diametri accommodatas, et compositiones polymerorum provectas quae degradatio environmentali resistunt. Processus fabricationis technologiam extrusionis primi ordinis incorporat, dimensionalem constantiam et integritatem structuralem per totam longitudinem tubi certificans. Hi tubi exceptionalem resistentiam chimicam demonstrant, eosque ideales ad applicationes substantiarum corrosivarum vel condicionum ambientalium difficilium pertinentes reddunt. Tubus PVC personalisatus plenus magnitudinis fortitudinem tentionalem superiorem exhibet respectu materialium ductilium traditionalium, simul flexibilitate retenta ad casus installationis complexos necessarios. Stabilitas thermalis inter -20°F et 140°F variat, varia condiciona climatica sustinens sine defectu caracterum functionalis. Applicationes per infrastructuram telecommunicationum patescunt, ubi hi tubi cabos fibrae opticae ab iniuria mechanica et expositione ambientali tuentur. Systemata municipalia aquarum ex proprietatibus non toxicis et superficie interna lene gaudent, quae incrementum bacterialis prohibet et qualitatem aquae conservat. Facilitates industriales tubum PVC personalisatum plenum magnitudinis ad lineas tractationis chemicas, systemata aeris compressi, et applicationes gestionis sterquilinii utuntur. Pars personalisationis ingenieros permittit dimensiones exactas, taxationes pressionis, et figuras specialis praecise requisitis proiecti accomodare. Installationes subterraneae ex resistentia tubi ad chemica terrae, penetratione radicum, et stressibus motus terrae maxime gaudent. Opera constructionis hos tubos propter naturam leviorem eorum amant, quae onera transportandi minuit et procedurae installationis facillimas reddit, nec machinationem gravem requirunt.