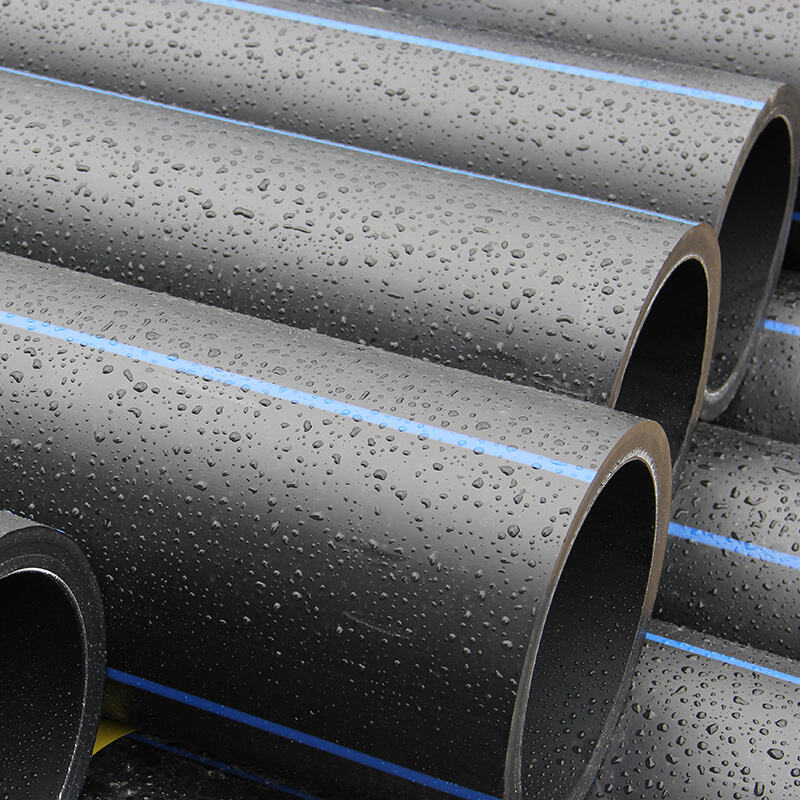

hdpe corrugated pipe

HDPE corrugated pipe represents a revolutionary advancement in modern drainage and infrastructure solutions, combining high-density polyethylene construction with innovative corrugated design principles. This specialized piping system features alternating ridges and valleys along its exterior surface, creating a structure that maximizes strength while maintaining flexibility and lightweight characteristics. The corrugated profile significantly enhances the pipe's ring stiffness, allowing it to withstand substantial external loads and soil pressure without compromising structural integrity. Manufactured through advanced extrusion processes, hdpe corrugated pipe delivers exceptional performance across diverse environmental conditions and installation scenarios. The smooth interior surface promotes efficient fluid flow with minimal friction losses, while the corrugated exterior provides superior soil engagement and load distribution capabilities. These pipes incorporate cutting-edge polymer technology that ensures long-term chemical resistance, UV stability, and mechanical durability. The manufacturing process utilizes virgin HDPE resins that meet stringent quality standards, resulting in pipes with consistent wall thickness and dimensional accuracy. Technological features include flexible joint systems that accommodate ground movement, thermal expansion, and seismic activity without failure. The modular design allows for efficient transportation, storage, and installation, reducing project costs and timeline requirements. Primary applications encompass stormwater management systems, agricultural drainage networks, culvert replacements, septic system components, and industrial wastewater conveyance. Municipal infrastructure projects frequently specify hdpe corrugated pipe for its proven performance in challenging soil conditions and aggressive environments. The pipe's lightweight nature simplifies handling and installation procedures, reducing labor requirements and equipment costs. Advanced manufacturing techniques ensure precise dimensional control and consistent quality throughout production runs, meeting or exceeding international standards for buried plastic pipe systems.