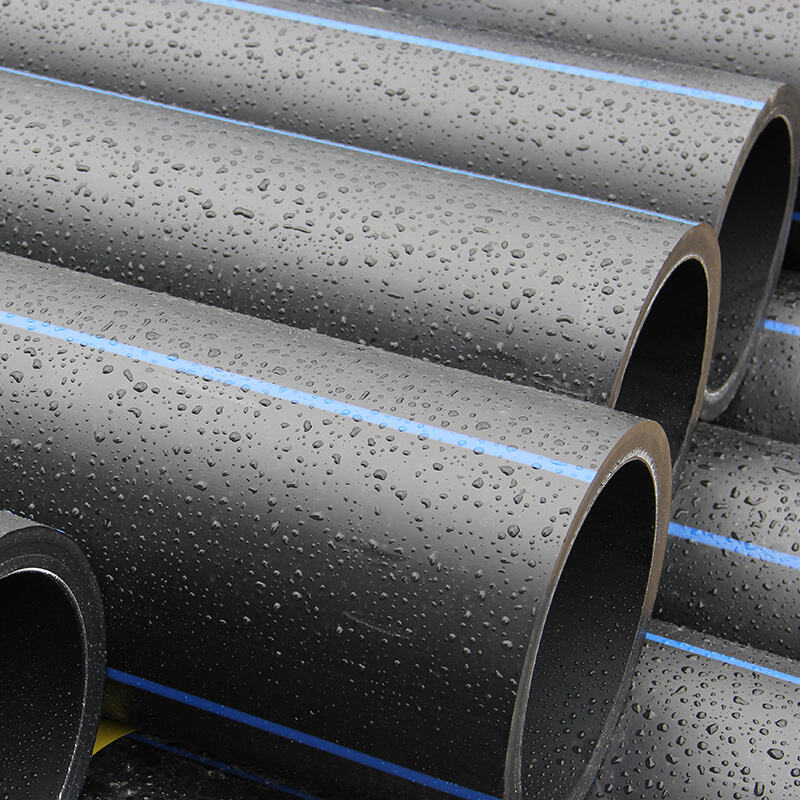

hdpe pe100 pipe specifications

HDPE PE100 pipe specifications represent the pinnacle of modern plastic piping technology, delivering exceptional performance across diverse infrastructure applications. These high-density polyethylene pipes feature advanced molecular structure engineering that provides superior strength-to-weight ratios compared to traditional piping materials. The PE100 designation indicates the material's minimum required strength classification, ensuring consistent quality and reliability in demanding applications. HDPE PE100 pipe specifications incorporate cutting-edge polymer science, utilizing advanced catalytic processes to achieve optimal molecular chain distribution. This sophisticated manufacturing approach results in pipes that demonstrate remarkable resistance to environmental stress cracking, chemical corrosion, and impact damage. The specifications encompass comprehensive dimensional standards, pressure ratings, and performance characteristics that meet international quality benchmarks. These pipes function primarily as conduits for water distribution, gas transmission, and industrial fluid transport systems. The technological features of HDPE PE100 pipe specifications include exceptional flexibility, allowing installation around obstacles without requiring numerous fittings. The material exhibits outstanding UV resistance when properly formulated, ensuring long-term performance in exposed applications. Thermal expansion characteristics remain manageable within normal operating temperature ranges, contributing to system stability. Applications for HDPE PE100 pipe specifications span municipal water systems, natural gas distribution networks, industrial process piping, mining operations, and agricultural irrigation systems. The specifications accommodate various jointing methods including electrofusion welding, butt fusion welding, and mechanical connections. These pipes demonstrate remarkable longevity, with properly installed systems maintaining structural integrity for decades. The specifications also address environmental considerations, as HDPE materials are fully recyclable and contribute to sustainable infrastructure development. Installation versatility represents another key aspect of HDPE PE100 pipe specifications, enabling trenchless installation methods that minimize surface disruption and reduce project costs.