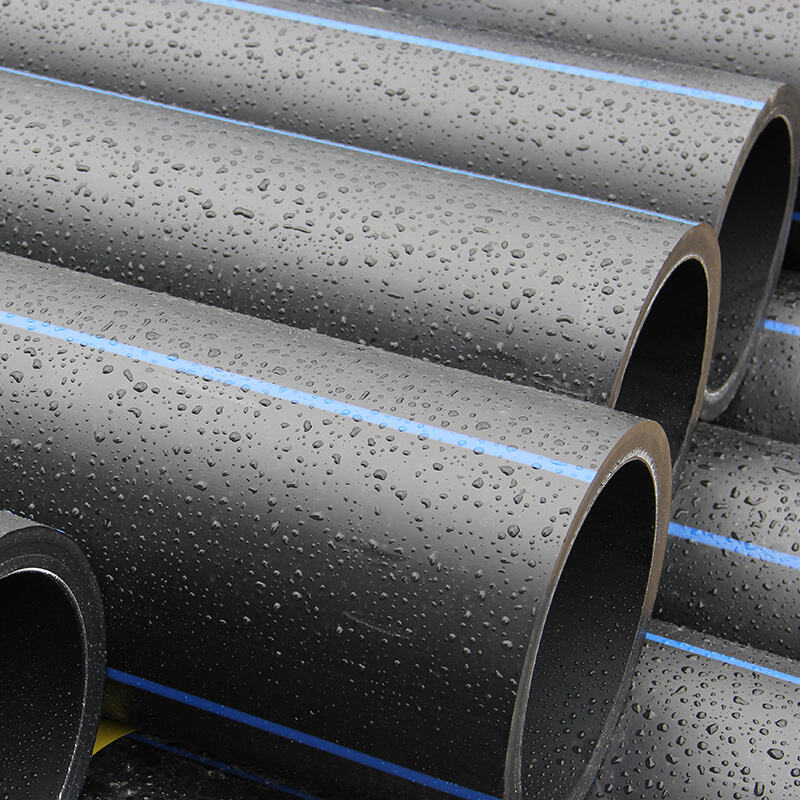

Superior Chemical Resistance and Environmental Durability

The 4 inch hdpe pipe demonstrates unparalleled chemical resistance that makes it the preferred choice for challenging applications where traditional materials fail prematurely. This exceptional resistance stems from the polymer's molecular structure, which remains stable when exposed to acids, bases, salts, and organic compounds that would quickly corrode metal pipes or degrade other plastic materials. Industrial facilities processing chemicals, pharmaceuticals, or corrosive substances rely on this pipe's ability to maintain structural integrity without requiring expensive protective linings or frequent replacements. The material resists stress cracking even when exposed to harsh chemicals under pressure, ensuring long-term reliability in demanding environments. Environmental factors that destroy conventional piping systems have minimal impact on the 4 inch hdpe pipe. UV radiation from sunlight, which degrades many plastic materials, cannot penetrate the stabilized polymer matrix, allowing for decades of outdoor exposure without brittleness or color fading. Soil conditions that accelerate corrosion in buried metal pipes, including high salinity, acidic conditions, or stray electrical currents, pose no threat to the chemically inert polymer structure. Temperature cycling that causes expansion and contraction stress in rigid materials is accommodated by the pipe's flexibility, preventing crack formation and joint failure. The material's resistance to biological attack eliminates concerns about bacterial degradation or root intrusion that can compromise other piping materials. This comprehensive durability translates into substantial cost savings over the system's lifespan, as property owners avoid expensive repairs, replacements, and associated downtime. The 4 inch hdpe pipe maintains its performance characteristics throughout its extended service life, providing consistent flow rates and pressure capabilities without the gradual deterioration experienced with alternative materials. This reliability proves particularly valuable in critical applications where system failure could result in environmental damage, production losses, or safety hazards.