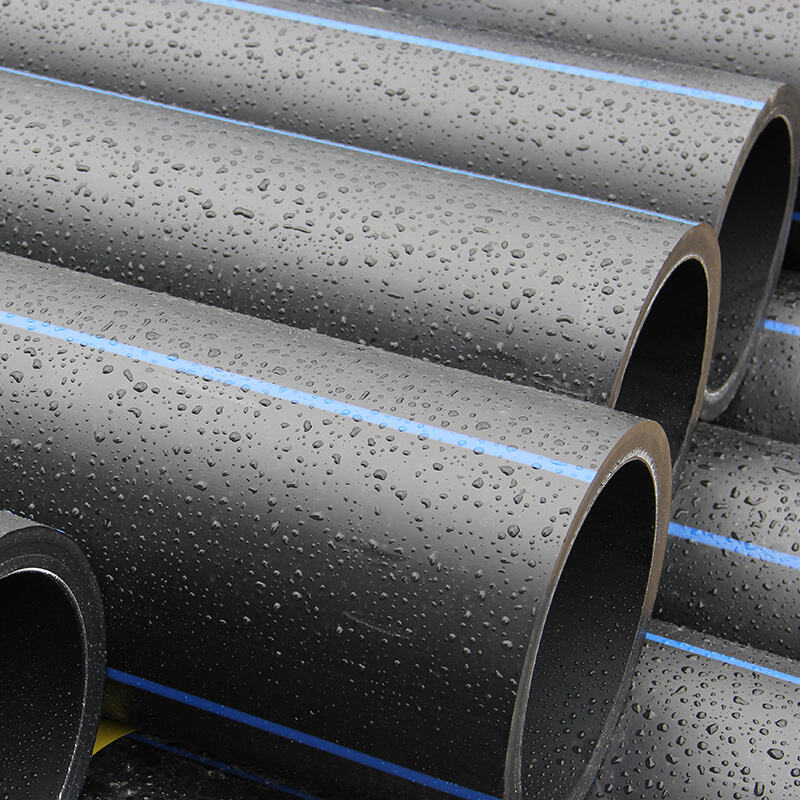

hdpe pipe price

HDPE pipe price represents one of the most significant considerations for construction professionals, infrastructure developers, and industrial project managers seeking reliable piping solutions. High-Density Polyethylene pipes have revolutionized the modern piping industry through their exceptional durability, chemical resistance, and cost-effectiveness. Understanding the hdpe pipe price structure involves examining multiple factors including diameter specifications, wall thickness requirements, pressure ratings, and installation complexities. The technological foundation of HDPE pipes centers on advanced polymer engineering that creates lightweight yet incredibly strong piping systems capable of withstanding extreme environmental conditions. These pipes demonstrate remarkable flexibility during installation while maintaining structural integrity under high-pressure applications. The hdpe pipe price varies significantly based on manufacturing standards, with pipes meeting international certifications commanding premium pricing due to enhanced quality assurance. Primary applications span municipal water distribution systems, natural gas transportation networks, industrial chemical processing facilities, agricultural irrigation projects, and residential plumbing installations. The material composition utilizes high-density polyethylene resin that provides superior resistance to corrosion, chemical degradation, and environmental stress cracking. Manufacturing processes involve sophisticated extrusion techniques that ensure consistent wall thickness and dimensional accuracy throughout pipe lengths. The hdpe pipe price reflects advanced production technologies that incorporate quality control measures at every manufacturing stage. Key technological features include fusion welding capabilities that create seamless joint connections, thermal expansion characteristics that accommodate temperature fluctuations, and UV stabilization properties that prevent material degradation under direct sunlight exposure. Installation versatility allows for both underground burial and above-ground mounting configurations, making these pipes suitable for diverse project requirements. The hdpe pipe price consideration becomes particularly important when evaluating long-term operational costs, as these pipes typically offer service lives exceeding fifty years with minimal maintenance requirements, ultimately providing exceptional value propositions for infrastructure investments.