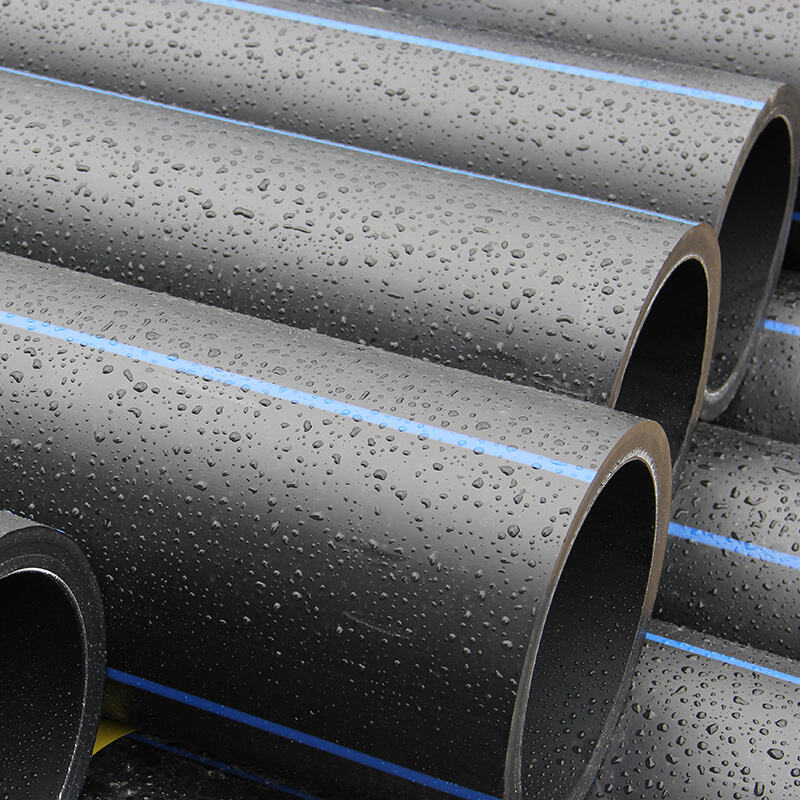

hdpe gas pipe

HDPE gas pipe represents a revolutionary advancement in natural gas distribution systems, utilizing high-density polyethylene material to create superior piping solutions for residential, commercial, and industrial applications. This innovative pipeline technology combines exceptional durability with cost-effective installation methods, making it the preferred choice for modern gas infrastructure projects worldwide. The hdpe gas pipe system operates through advanced fusion welding techniques that create seamless, leak-proof joints throughout the entire network. These pipes excel in transporting natural gas from distribution points to end-users while maintaining optimal pressure levels and ensuring safety standards. The technological foundation of hdpe gas pipe construction involves specialized manufacturing processes that enhance molecular structure, resulting in pipes with outstanding chemical resistance and mechanical properties. Key functions include reliable gas transportation, pressure maintenance, and long-term service performance in various environmental conditions. The hdpe gas pipe demonstrates remarkable flexibility, allowing installation around obstacles without requiring numerous fittings or joints that could potentially compromise system integrity. Applications span across urban gas distribution networks, rural pipeline extensions, industrial facility connections, and emergency repair situations where rapid deployment is essential. The pipe's lightweight nature significantly reduces transportation costs and installation time compared to traditional metal alternatives. Advanced manufacturing techniques ensure consistent wall thickness and dimensional accuracy, contributing to reliable performance throughout the pipeline's operational lifespan. The hdpe gas pipe incorporates innovative design features that resist corrosion, chemical degradation, and environmental stress, making it suitable for diverse geographic regions and climate conditions. Installation versatility allows for both underground burial and above-ground mounting configurations, providing engineers with flexible design options for complex routing requirements.