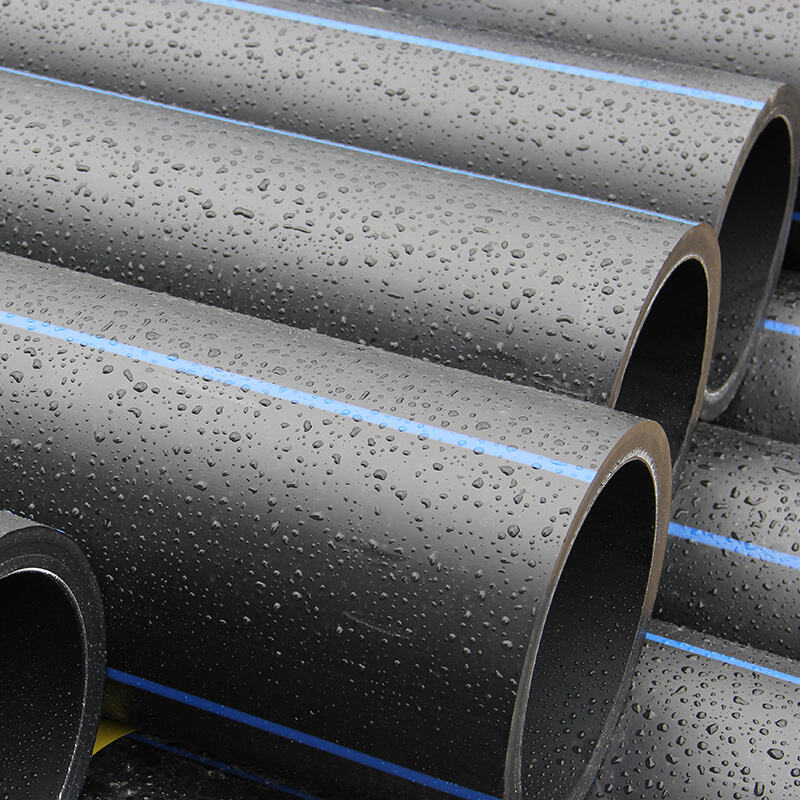

hdpe pipes

HDPE pipes represent a revolutionary advancement in modern piping systems, manufactured from high-density polyethylene that delivers exceptional performance across diverse applications. These innovative pipes serve as the backbone for water distribution networks, gas transmission systems, and industrial fluid transport solutions worldwide. The primary functions of HDPE pipes encompass potable water delivery, wastewater management, natural gas distribution, and chemical transfer operations in various industries. Their technological features include superior molecular structure that provides enhanced strength-to-weight ratios, making them lighter yet stronger than traditional materials. The manufacturing process involves advanced extrusion techniques that create seamless pipe walls with consistent thickness and diameter precision. HDPE pipes demonstrate remarkable flexibility, allowing installation in challenging terrains without compromising structural integrity. Their smooth interior surface reduces friction losses, improving flow efficiency and reducing energy consumption in pumping systems. The material exhibits excellent resistance to environmental stress cracking, ensuring long-term reliability under varying pressure conditions. Applications span municipal water systems, agricultural irrigation networks, mining operations, marine outfalls, and residential plumbing installations. Industrial applications include chemical processing plants, food and beverage facilities, and pharmaceutical manufacturing where purity and contamination prevention are critical. The joining methods for HDPE pipes include heat fusion welding, electrofusion coupling, and mechanical connections, providing versatile installation options for different project requirements. These pipes maintain their performance characteristics across temperature ranges from -40°C to 60°C, making them suitable for diverse climatic conditions. The material's inherent properties resist bacterial growth and biofilm formation, maintaining water quality throughout distribution systems. Environmental considerations make HDPE pipes increasingly popular, as they are fully recyclable and contribute to sustainable infrastructure development practices.