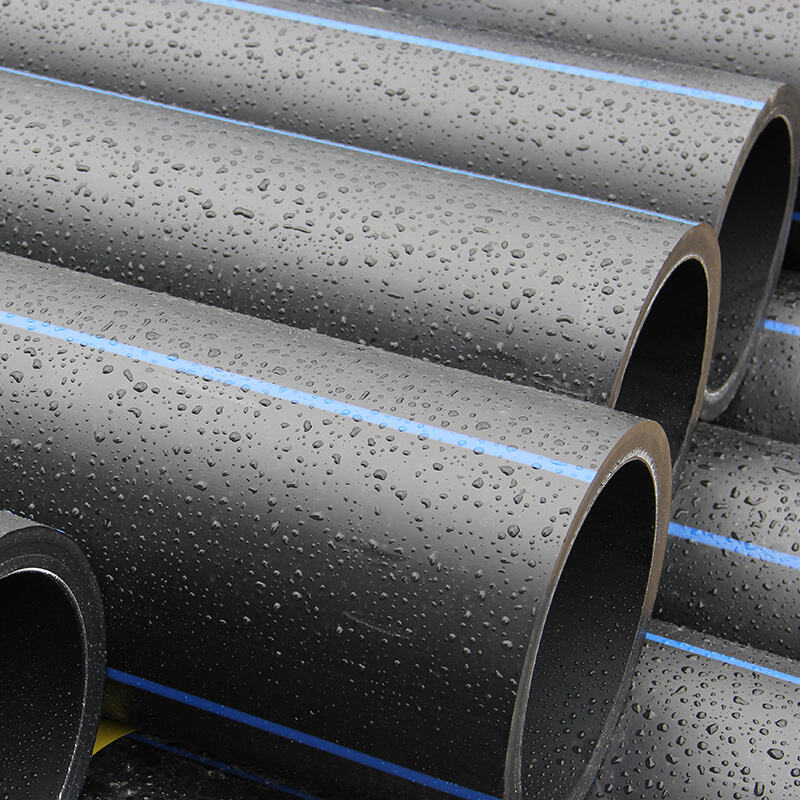

Superior Corrosion Resistance and Chemical Compatibility

The exceptional corrosion resistance of black hdpe pipe represents one of its most valuable characteristics for customers operating in challenging environments. Unlike metallic piping systems that suffer from electrochemical corrosion, galvanic action, and chemical attack, black hdpe pipe maintains its structural integrity when exposed to aggressive chemicals, acidic soils, and saltwater environments. This resistance stems from the inert nature of high-density polyethylene, which does not react with most chemicals commonly encountered in industrial and municipal applications. The material resists attack from acids, bases, salts, and organic compounds that would rapidly degrade steel, iron, or concrete pipes. This chemical compatibility extends the service life significantly while eliminating the need for protective coatings, cathodic protection systems, or chemical inhibitors. Customers benefit from reduced lifecycle costs as maintenance requirements become minimal compared to traditional piping materials. The smooth, non-reactive surface prevents scale buildup and biological fouling that commonly plague other pipe materials, maintaining system efficiency and flow capacity over time. In marine applications, black hdpe pipe performs exceptionally well against saltwater corrosion that destroys metal pipes within years. Municipal water systems benefit from the material's resistance to chlorine and other water treatment chemicals that accelerate the degradation of alternative piping materials. Industrial facilities handling process chemicals find black hdpe pipe provides reliable service without contamination concerns or unexpected failures. The corrosion resistance also extends to external environments, where aggressive soils containing sulfates, chlorides, or organic acids cannot penetrate or damage the pipe structure. This characteristic proves particularly valuable in coastal areas, industrial sites, and regions with naturally aggressive soil conditions. The elimination of corrosion-related failures reduces emergency repairs, system downtime, and associated costs while improving overall system reliability and customer satisfaction.