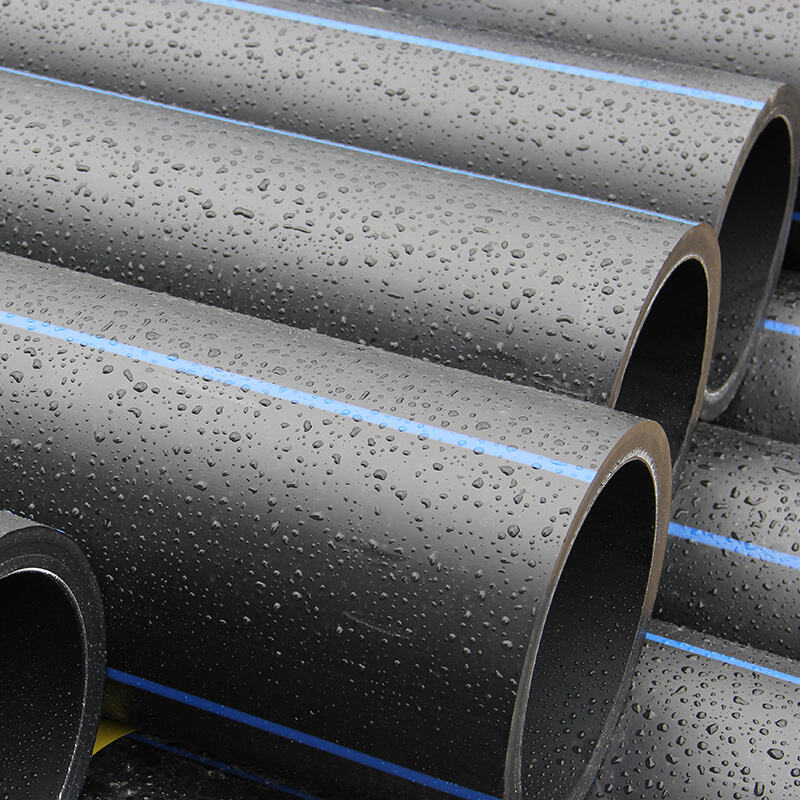

hdpe black pipe

HDPE black pipe represents a revolutionary advancement in piping technology, offering exceptional performance across numerous industrial and commercial applications. High-density polyethylene construction provides superior durability and resistance to environmental factors that commonly affect traditional piping materials. The distinctive black coloration results from carbon black additives that enhance UV resistance and thermal stability, making these pipes ideal for outdoor installations and underground applications. HDPE black pipe systems demonstrate remarkable flexibility while maintaining structural integrity under various pressure conditions. The material exhibits excellent chemical resistance properties, withstanding exposure to acids, alkalis, and various corrosive substances without degradation. Manufacturing processes utilize advanced extrusion techniques that ensure consistent wall thickness and dimensional accuracy throughout the entire pipe length. The smooth interior surface of HDPE black pipe promotes efficient flow characteristics with minimal friction loss, resulting in energy savings and improved system performance. Installation procedures are simplified due to the lightweight nature of the material, reducing labor costs and project timelines significantly. Fusion welding capabilities enable seamless joint connections that eliminate potential leak points and ensure long-term system reliability. HDPE black pipe applications span water distribution networks, gas transmission systems, mining operations, industrial process piping, and telecommunications conduit installations. The material demonstrates exceptional impact resistance even at low temperatures, maintaining performance integrity in harsh environmental conditions. Thermal expansion properties are well-understood and easily accommodated through proper design considerations and installation techniques. Quality control standards ensure each HDPE black pipe meets stringent industry specifications for pressure ratings, dimensional tolerances, and material properties. Environmental sustainability considerations make HDPE black pipe an attractive choice, as the material is fully recyclable and contributes to reduced carbon footprint compared to traditional materials. Service life expectations exceed fifty years under normal operating conditions, providing exceptional value and reliability for infrastructure investments.