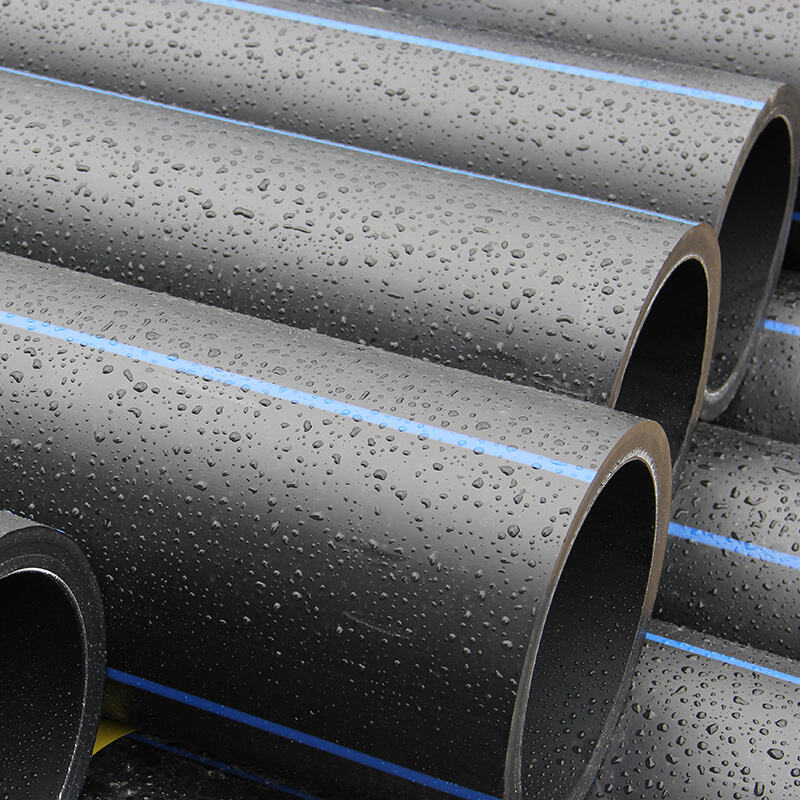

dwc hdpe pipe

The DWC HDPE pipe, also known as Double Wall Corrugated High-Density Polyethylene pipe, represents a revolutionary advancement in modern piping technology. This innovative pipe system features a unique dual-wall construction that combines exceptional strength with lightweight properties. The DWC HDPE pipe consists of an internal smooth wall that ensures optimal flow characteristics and an external corrugated structure that provides superior ring stiffness and load-bearing capacity. The main functions of DWC HDPE pipe include drainage systems, sewerage applications, cable protection, and underground utility installations. These pipes excel in handling both gravity-fed and pressure applications across residential, commercial, and industrial sectors. The technological features of DWC HDPE pipe include excellent chemical resistance, long-term durability, and flexible installation options. The corrugated exterior design distributes loads evenly while maintaining structural integrity under various soil conditions. The smooth interior surface minimizes friction losses and prevents sediment buildup, ensuring consistent flow rates throughout the pipe's operational lifetime. DWC HDPE pipe applications span multiple industries including municipal infrastructure, telecommunications, electrical utilities, and stormwater management systems. These pipes are particularly effective for culvert installations, foundation drainage, and underground cable conduits. The manufacturing process utilizes advanced extrusion technology that creates a seamless bond between the inner and outer walls, eliminating potential failure points. Environmental considerations make DWC HDPE pipe an excellent choice for sustainable construction projects, as the material is fully recyclable and produces minimal environmental impact during production and installation. The pipe's resistance to corrosion, abrasion, and chemical attack ensures reliable performance in challenging underground environments where traditional materials might fail.