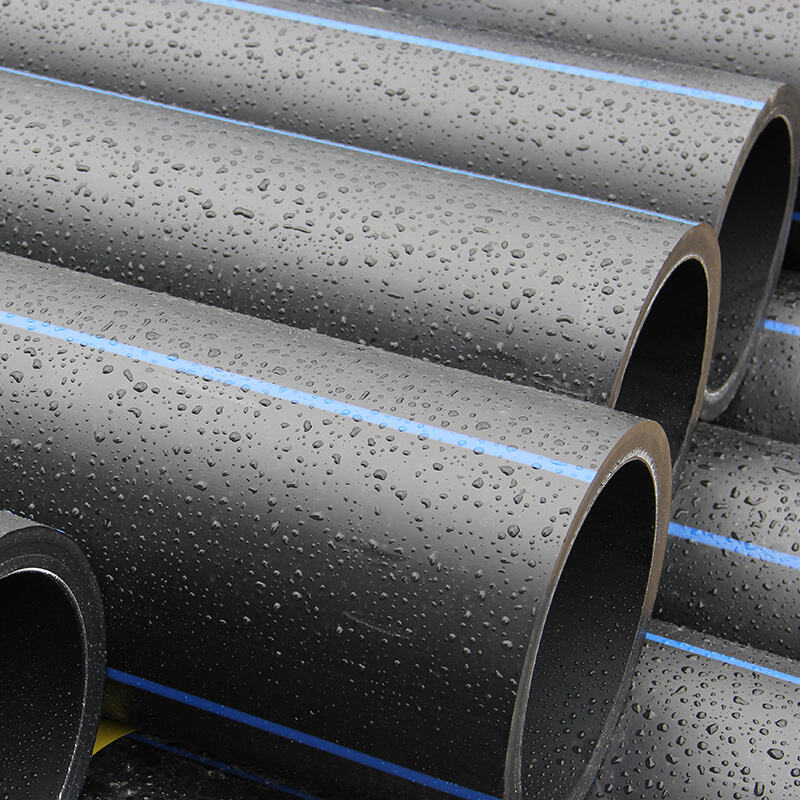

hdpe drainage pipe

HDPE drainage pipe represents a revolutionary advancement in modern water management systems, combining cutting-edge polymer technology with exceptional engineering design. High-density polyethylene forms the foundation of these drainage solutions, delivering unmatched performance across residential, commercial, and industrial applications. The primary function of hdpe drainage pipe centers on efficient water collection, conveyance, and disposal, making it indispensable for subsurface drainage, stormwater management, and agricultural irrigation systems. These pipes feature advanced corrugated exterior walls that provide superior structural integrity while maintaining smooth interior surfaces for optimal flow characteristics. The dual-wall construction maximizes strength-to-weight ratios, enabling installation in challenging soil conditions without compromising performance. Technological innovations in hdpe drainage pipe manufacturing include precision extrusion processes that ensure consistent wall thickness, enhanced joint designs for leak-proof connections, and specialized perforation patterns that optimize water infiltration rates. The material composition exhibits remarkable chemical resistance, withstanding exposure to acids, alkalis, and various soil chemicals that typically degrade conventional materials. Temperature stability allows these pipes to function effectively across wide thermal ranges, from freezing winter conditions to extreme summer heat. Flexibility characteristics enable hdpe drainage pipe systems to accommodate ground settlement and seismic activity without structural failure. Applications span numerous sectors including agricultural field drainage, highway underdrain systems, residential foundation protection, commercial building water management, and municipal stormwater infrastructure. The manufacturing process incorporates recycled content, supporting sustainable construction practices while maintaining product quality standards. Installation versatility allows for both open-trench and trenchless methods, reducing project timelines and site disruption. Quality control measures ensure each hdpe drainage pipe meets stringent industry specifications for dimensional accuracy, structural performance, and environmental compliance.