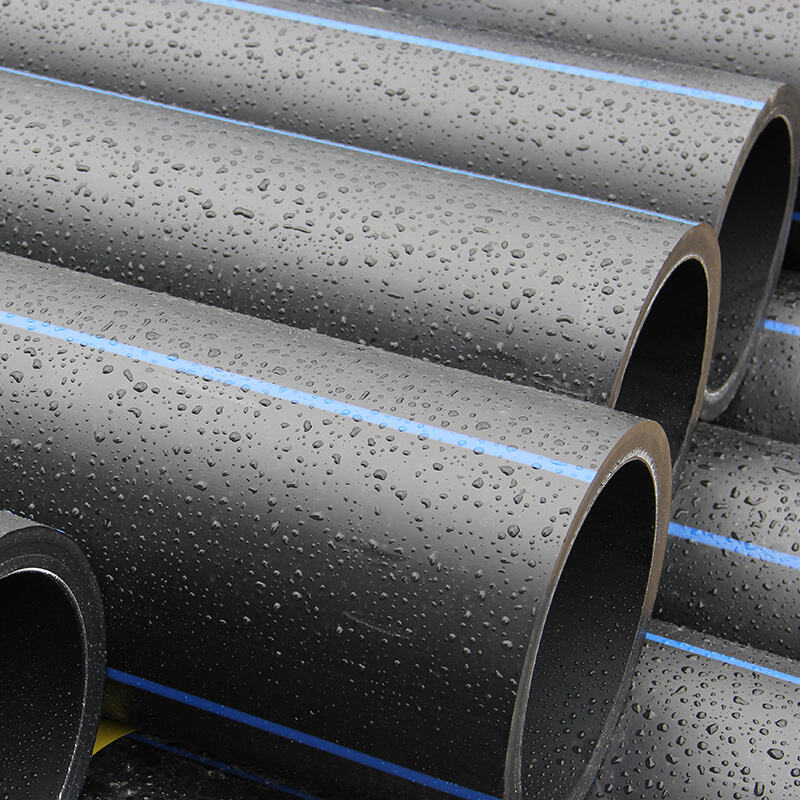

hdpe water pipe

HDPE water pipe represents a revolutionary advancement in modern water distribution systems, offering exceptional performance characteristics that make it the preferred choice for municipal, industrial, and residential applications. High-Density Polyethylene (HDPE) water pipe systems utilize advanced polymer technology to deliver superior durability, flexibility, and chemical resistance compared to traditional piping materials. These pipes are manufactured through sophisticated extrusion processes that ensure consistent wall thickness and molecular structure throughout the entire length. The primary functions of HDPE water pipe include potable water distribution, wastewater collection, irrigation systems, and industrial fluid transport. The technological features of these pipes encompass excellent fusion welding capabilities, allowing for seamless joint connections that eliminate potential leak points common in conventional piping systems. HDPE water pipe demonstrates remarkable resistance to environmental stress cracking, maintaining structural integrity under varying pressure conditions and temperature fluctuations. The smooth interior surface of HDPE water pipe minimizes friction losses, resulting in improved flow rates and reduced energy consumption for pumping systems. These pipes exhibit outstanding chemical inertness, preventing contamination of transported fluids and ensuring long-term water quality preservation. Applications for HDPE water pipe span across diverse sectors including municipal water supply networks, agricultural irrigation infrastructure, mining operations, and geothermal systems. The lightweight nature of HDPE water pipe significantly reduces installation costs and labor requirements while maintaining exceptional strength-to-weight ratios. Modern HDPE water pipe manufacturing incorporates UV stabilizers and antioxidants that enhance outdoor performance and extend service life beyond traditional materials. The flexibility of HDPE water pipe allows for installation in challenging terrain conditions, reducing the need for fittings and joints that could compromise system integrity.