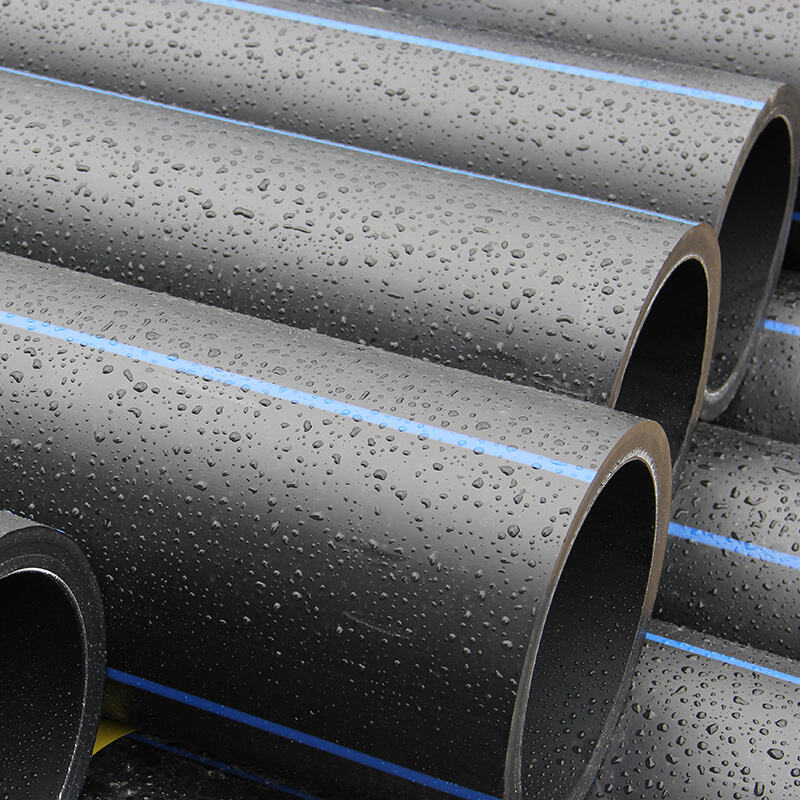

hdpe pipe black

HDPE pipe black represents a revolutionary advancement in modern piping infrastructure, combining exceptional durability with versatile functionality across numerous industries. High-Density Polyethylene (HDPE) pipe black is manufactured through advanced extrusion processes that incorporate carbon black additives, providing superior UV resistance and enhanced structural integrity. This specialized piping solution offers remarkable chemical resistance, making it ideal for transporting various fluids including potable water, wastewater, industrial chemicals, and gas distribution systems. The black coloration serves multiple purposes beyond aesthetics, acting as a protective barrier against ultraviolet radiation while maintaining the pipe's molecular stability over extended periods. HDPE pipe black demonstrates exceptional flexibility, allowing installation in challenging terrains without compromising structural integrity. The material's inherent properties enable it to withstand temperature fluctuations ranging from -40°F to 140°F, making it suitable for diverse climatic conditions. Manufacturing standards ensure consistent wall thickness and diameter precision, guaranteeing reliable performance in pressure applications up to 200 PSI. The pipe's smooth interior surface minimizes friction losses, optimizing flow rates and reducing energy consumption in pumping systems. Installation procedures are streamlined through various joining methods including heat fusion, mechanical fittings, and electrofusion techniques. Environmental sustainability remains a key characteristic, as HDPE pipe black maintains recyclability while offering service lives exceeding 50 years. Quality control measures during production include comprehensive testing for tensile strength, impact resistance, and dimensional accuracy. The material's non-toxic composition ensures safe contact with drinking water, meeting stringent health regulations. Corrosion resistance eliminates concerns about metal degradation, reducing maintenance requirements and operational costs. Advanced manufacturing techniques produce pipes in diameters ranging from half-inch residential applications to large-scale infrastructure projects exceeding 60 inches. These comprehensive features establish HDPE pipe black as the preferred choice for modern piping solutions.