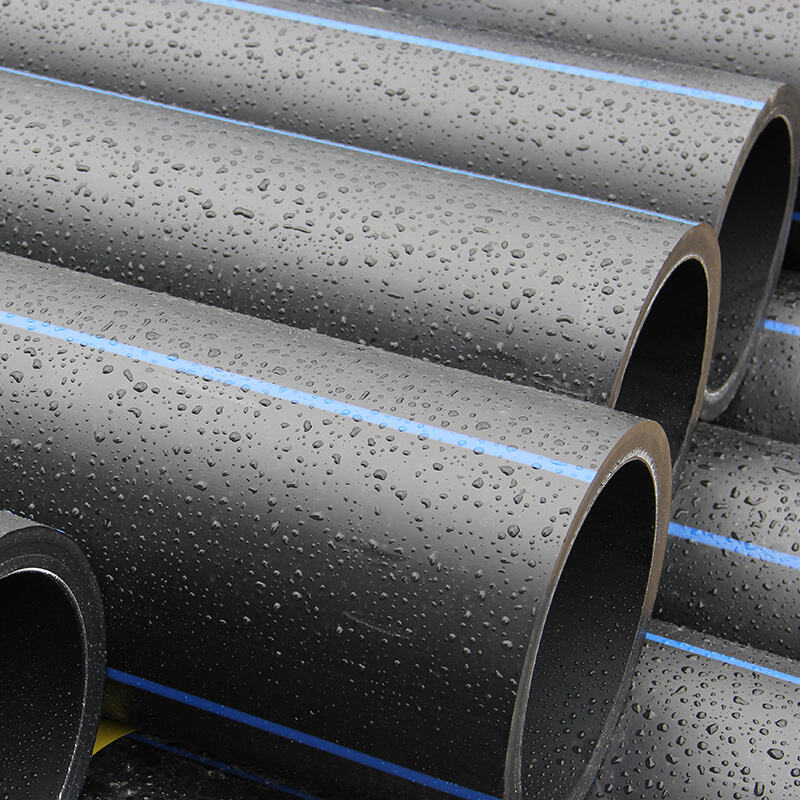

hdpe 100 pipe

HDPE 100 pipe represents the pinnacle of high-density polyethylene piping technology, engineered to meet the most demanding industrial and municipal applications. This advanced piping system belongs to the PE100 classification, which indicates its superior stress crack resistance and long-term hydrostatic strength properties. The hdpe 100 pipe is manufactured using specialized resin compounds that provide exceptional durability and performance characteristics far exceeding conventional plastic piping solutions. The main functions of hdpe 100 pipe encompass water distribution, gas transmission, sewerage systems, industrial process piping, and telecommunications ducting. Its technological features include outstanding chemical resistance, flexibility during installation, and the ability to withstand extreme temperature variations without compromising structural integrity. The hdpe 100 pipe incorporates advanced molecular structure engineering that creates stronger intermolecular bonds, resulting in enhanced crack propagation resistance and extended service life expectations. Manufacturing processes involve precise temperature control and pressure management to ensure consistent wall thickness and optimal material properties throughout the pipe length. Applications for hdpe 100 pipe span across multiple industries including municipal water supply networks, natural gas distribution systems, mining operations, agricultural irrigation projects, and marine environments where corrosion resistance is paramount. The pipe's smooth internal surface reduces friction losses and maintains consistent flow rates over extended periods. Installation versatility allows for both above-ground and underground deployment, with joining methods including electrofusion welding, butt fusion welding, and mechanical fittings. Quality assurance protocols ensure that each hdpe 100 pipe meets stringent international standards for pressure ratings, dimensional accuracy, and material composition. The pipe's lightweight nature compared to traditional materials significantly reduces transportation costs and installation labor requirements while maintaining superior performance characteristics.