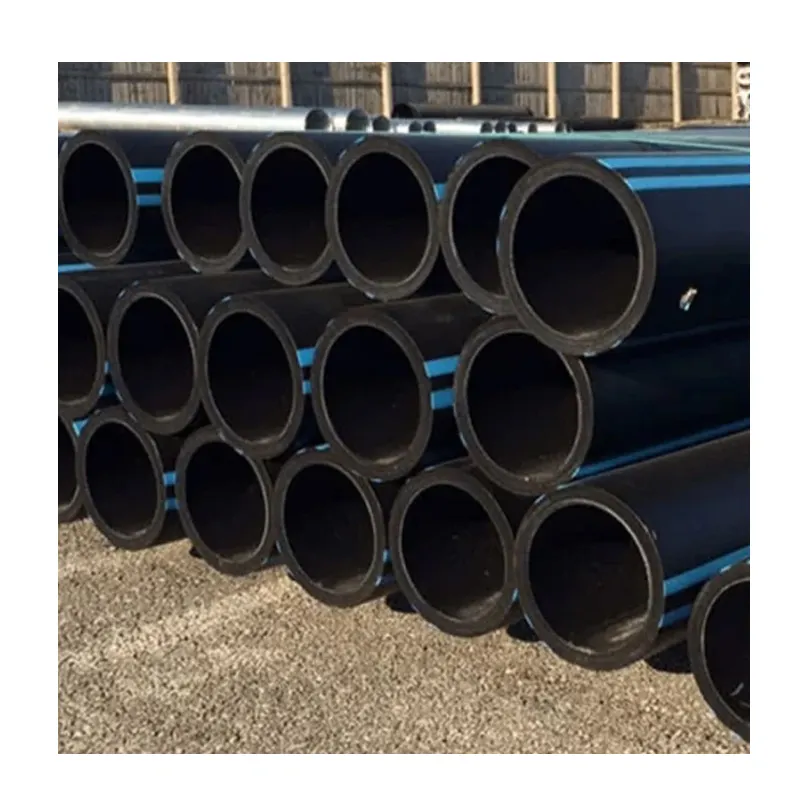

hdpe pipe for water supply

HDPE (High-Density Polyethylene) pipe for water supply represents a revolutionary advancement in modern plumbing infrastructure. These pipes are manufactured using high-grade polyethylene resins through an advanced extrusion process, resulting in a robust and reliable water transportation solution. The pipes feature exceptional durability with a service life exceeding 50 years under normal operating conditions. Their smooth inner surface significantly reduces friction losses, enabling efficient water flow and minimizing energy consumption during operation. HDPE pipes are characterized by their outstanding flexibility and corrosion resistance, making them ideal for both underground and above-ground installations. The material's chemical inertness ensures that water quality remains uncompromised, while its leak-proof fusion joining system creates a seamless network that virtually eliminates water loss. These pipes can withstand pressures up to 16 bars, depending on their size and wall thickness, and maintain their structural integrity across a wide temperature range from -40°C to 60°C. The installation process is streamlined through various joining methods, including butt fusion, electrofusion, and mechanical coupling, providing versatility in application scenarios. HDPE pipes have become increasingly popular in municipal water distribution, irrigation systems, and industrial water supply networks due to their cost-effectiveness and minimal maintenance requirements.