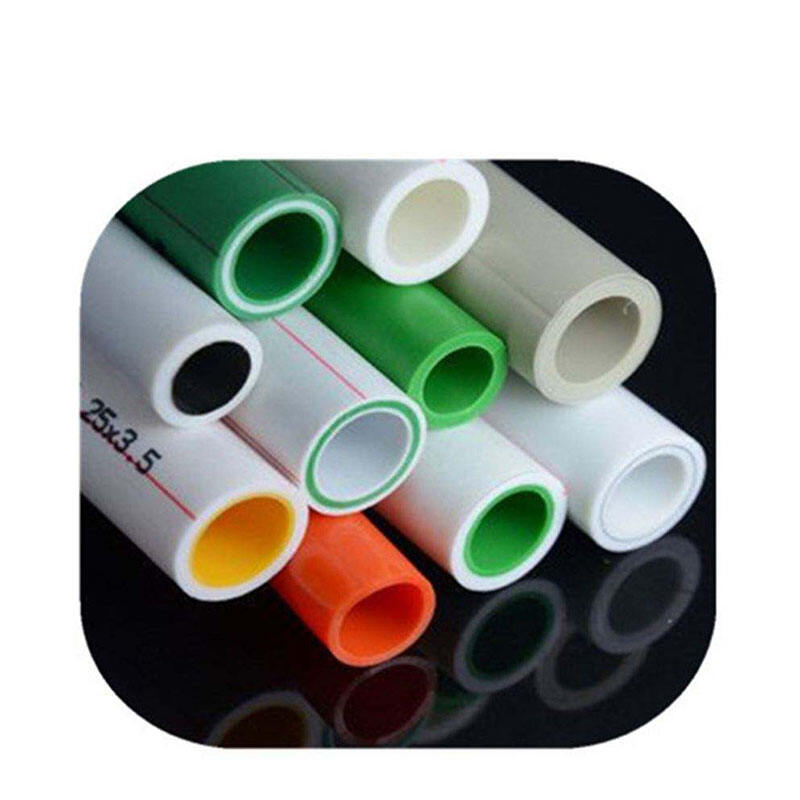

ppr pipe for heating

PPR pipe for heating represents a revolutionary advancement in modern plumbing and heating systems, offering exceptional performance and reliability for residential and commercial applications. Polypropylene Random Copolymer (PPR) pipes are specifically engineered to withstand high temperatures and pressures, making them ideal for hot water distribution and heating systems. These pipes feature a unique molecular structure that provides superior thermal stability and chemical resistance compared to traditional piping materials. The ppr pipe for heating operates efficiently at temperatures up to 95°C for continuous service and can handle short-term temperatures of 110°C, ensuring optimal performance in various heating applications. The technological features of ppr pipe for heating include excellent thermal conductivity properties, smooth interior surfaces that prevent bacterial growth, and outstanding dimensional stability under varying temperature conditions. These pipes utilize advanced fusion welding technology, creating seamless joints that eliminate potential leak points and ensure system integrity. The manufacturing process involves precise temperature control and quality testing to guarantee consistent wall thickness and diameter tolerances. PPR pipe for heating applications span across underfloor heating systems, radiator connections, hot water supply lines, and commercial heating networks. The versatility of ppr pipe for heating makes it suitable for hospitals, schools, residential complexes, and industrial facilities where reliable hot water distribution is essential. Installation flexibility allows for both surface mounting and concealed installation methods, accommodating diverse architectural requirements. The lightweight nature of ppr pipe for heating simplifies transportation and installation processes while reducing labor costs and project timelines.