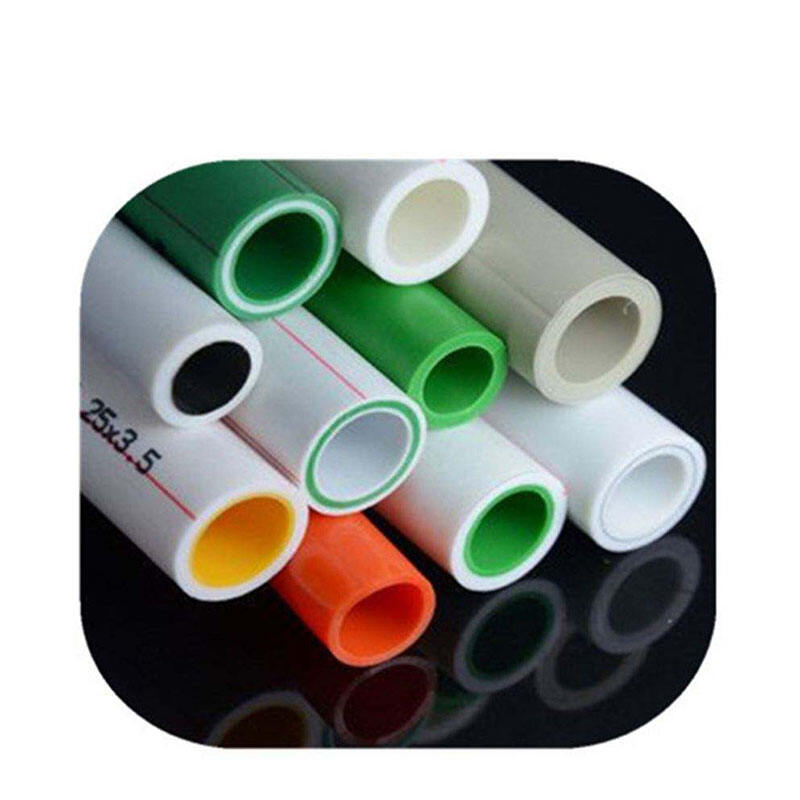

ppr pipe for cold water

PPR pipe for cold water represents a revolutionary advancement in modern plumbing systems, offering exceptional performance and reliability for residential, commercial, and industrial applications. Polypropylene Random Copolymer (PPR) technology delivers superior cold water distribution solutions that surpass traditional materials in durability, safety, and efficiency. These specialized pipes are engineered specifically to handle cold water temperatures ranging from 0°C to 20°C, making them ideal for drinking water systems, irrigation networks, and general cold water supply applications. The technological foundation of PPR pipe for cold water lies in its unique molecular structure, which provides excellent resistance to chemical corrosion, scaling, and bacterial growth. This advanced polymer composition ensures that water quality remains pristine throughout the distribution system, eliminating concerns about metallic taste or contamination that often plague metal piping systems. The manufacturing process incorporates precise temperature controls and quality assurance measures to guarantee consistent wall thickness and dimensional accuracy. PPR pipe for cold water features smooth internal surfaces that minimize friction losses and maintain optimal flow rates, resulting in improved system efficiency and reduced energy consumption. The material's inherent flexibility allows for easy installation around obstacles while maintaining structural integrity under varying pressure conditions. Installation versatility is enhanced through heat fusion welding techniques that create seamless, leak-proof joints without requiring additional sealing materials or chemicals. The lightweight nature of PPR pipe for cold water significantly reduces installation time and labor costs compared to heavier alternatives like copper or steel piping. These pipes demonstrate exceptional longevity with service life expectations exceeding 50 years under normal operating conditions, providing excellent return on investment for property owners and developers. Environmental sustainability is enhanced through the recyclable nature of PPR materials and the energy-efficient manufacturing process that reduces carbon footprint throughout the product lifecycle.