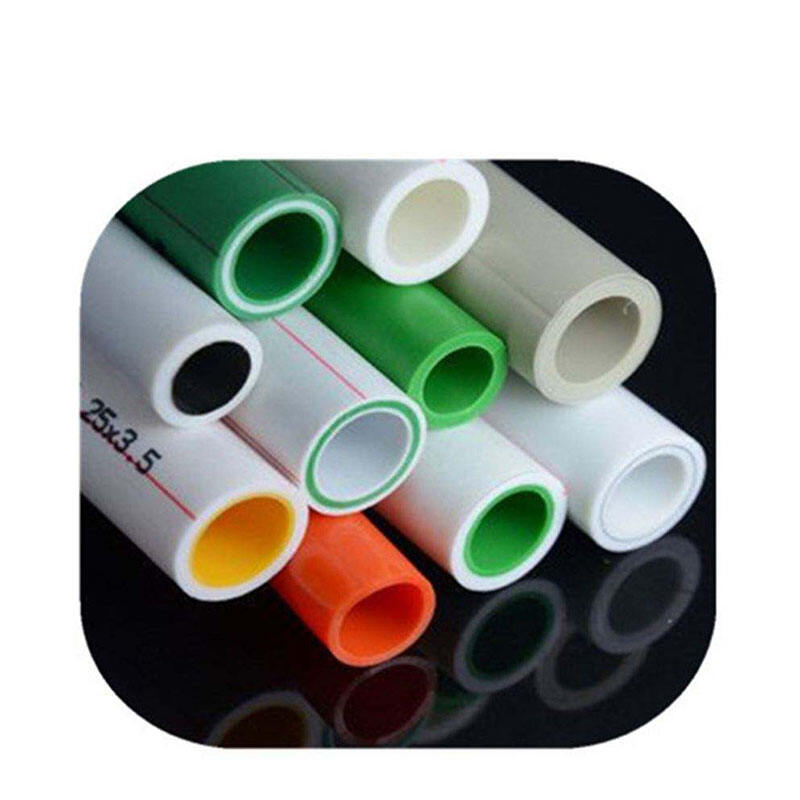

plastic pipework

Plastic pipework represents a revolutionary advancement in modern plumbing and industrial systems, offering superior performance across residential, commercial, and industrial applications. This innovative piping solution utilizes advanced polymer materials such as PVC, CPVC, PEX, and HDPE to create durable, flexible, and cost-effective distribution networks for water, gas, and various chemical substances. The main functions of plastic pipework encompass water supply distribution, drainage systems, heating and cooling networks, and specialized industrial fluid transport. These systems excel in delivering consistent flow rates while maintaining structural integrity under varying pressure conditions. The technological features of plastic pipework include enhanced chemical resistance, superior flexibility, and excellent thermal properties that adapt to temperature fluctuations without compromising performance. Modern plastic pipework incorporates advanced manufacturing techniques such as cross-linking processes and specialized additive compounds that enhance durability and extend service life. The lightweight nature of plastic pipework simplifies installation procedures while reducing labor costs and installation time. These systems demonstrate exceptional resistance to corrosion, scaling, and biological growth, ensuring long-term reliability in diverse environments. Applications span across municipal water systems, residential plumbing networks, industrial processing facilities, agricultural irrigation systems, and specialized chemical transport operations. The versatility of plastic pipework makes it suitable for underground installations, exposed outdoor environments, and temperature-controlled indoor applications. Quality plastic pipework systems feature smooth interior surfaces that minimize friction losses and optimize flow efficiency. The modular design approach allows for easy expansion and modification of existing systems without extensive reconstruction requirements. Advanced plastic pipework solutions incorporate smart monitoring capabilities and leak detection systems that enhance operational safety and maintenance efficiency.