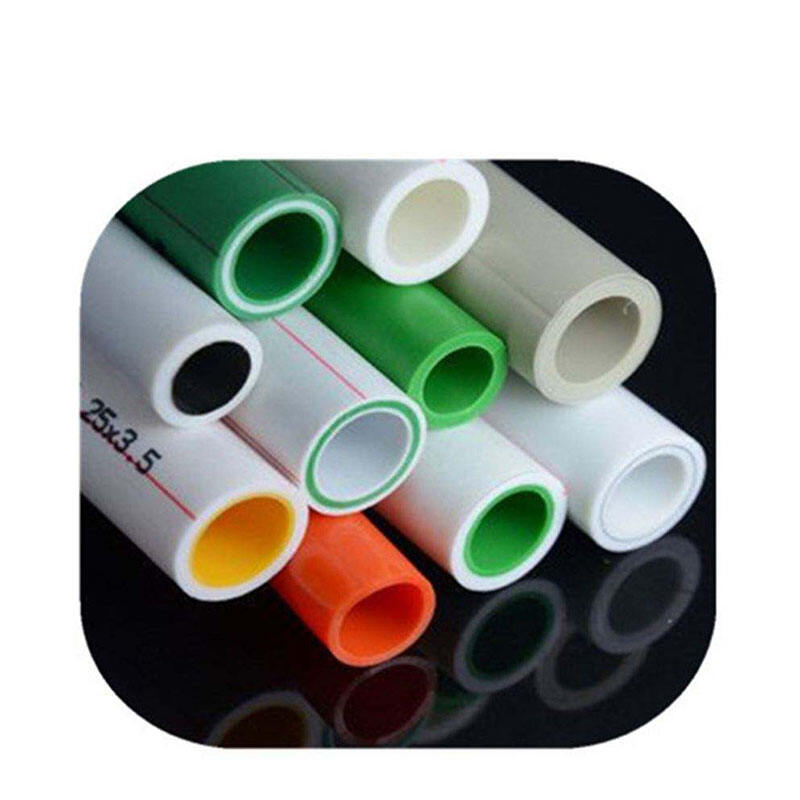

ppr pipe

PPR pipe, short for Polypropylene Random Copolymer pipe, represents a revolutionary advancement in modern plumbing and industrial piping systems. This innovative piping solution combines superior material science with practical engineering to deliver exceptional performance across diverse applications. The PPR pipe manufacturing process involves sophisticated polymer chemistry that creates a thermoplastic material with outstanding durability and versatility. These pipes feature a unique molecular structure that provides excellent resistance to chemical corrosion, temperature variations, and mechanical stress. The main functions of PPR pipe include water distribution in residential and commercial buildings, hot water circulation systems, industrial fluid transport, and specialized applications requiring high-temperature resistance. Technological features of PPR pipe encompass fusion welding capabilities that create seamless, leak-proof connections stronger than the pipe material itself. The smooth interior surface minimizes friction losses and prevents bacterial growth, ensuring optimal flow rates and hygienic water transport. PPR pipe systems demonstrate remarkable temperature tolerance, operating effectively in environments ranging from sub-zero conditions to temperatures exceeding 200 degrees Fahrenheit. The material composition includes stabilizers and additives that enhance UV resistance and prevent degradation from prolonged sunlight exposure. Applications for PPR pipe span multiple industries including residential plumbing, commercial HVAC systems, industrial process piping, agricultural irrigation networks, and specialized medical facility installations. The pipes are available in various diameters and pressure ratings to accommodate different system requirements. Installation versatility allows PPR pipe to be used in both concealed and exposed applications, making it suitable for new construction projects and renovation work. The lightweight nature of PPR pipe significantly reduces transportation costs and simplifies handling during installation procedures.