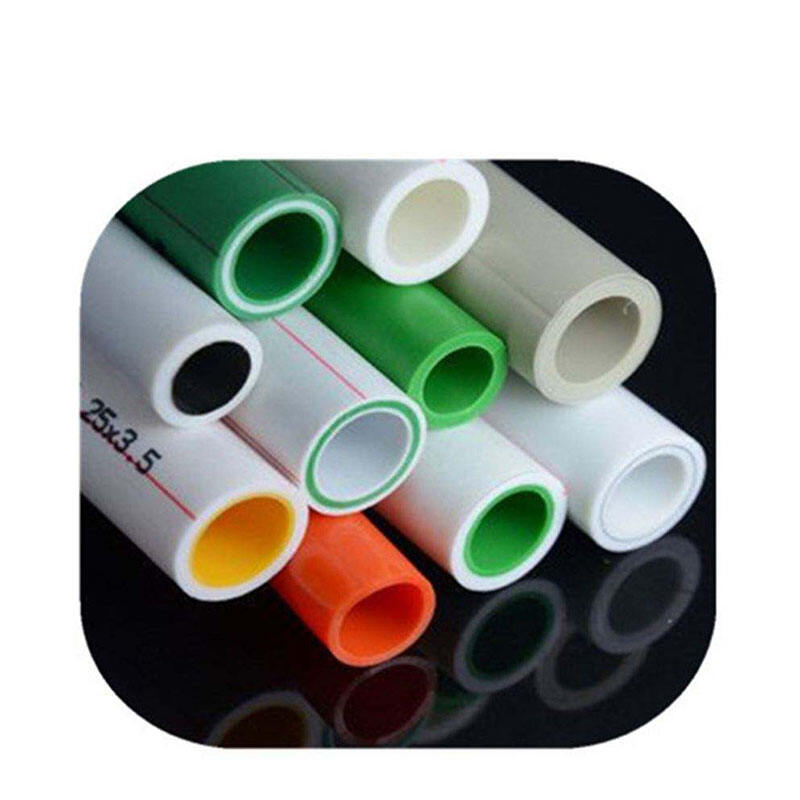

polypropylene piping systems

Polypropylene piping systems represent a cutting-edge solution in modern plumbing and industrial applications, offering exceptional performance across diverse environments. These advanced piping networks utilize polypropylene material, a thermoplastic polymer renowned for its outstanding chemical resistance and mechanical strength. The primary functions of polypropylene piping systems encompass water distribution, chemical transport, waste management, and industrial process applications. These systems excel in both residential and commercial settings, providing reliable fluid conveyance for heating, cooling, and general plumbing requirements. Technologically, polypropylene piping systems feature fusion welding capabilities that create seamless, leak-proof connections. The material exhibits excellent thermal stability, maintaining structural integrity across temperature ranges from -20°C to 95°C. Advanced manufacturing processes ensure consistent wall thickness and dimensional accuracy, contributing to optimal flow characteristics and pressure handling capabilities. The lightweight nature of polypropylene material simplifies installation procedures while reducing transportation costs. These piping systems incorporate innovative joint designs, including electrofusion and butt fusion techniques that eliminate the need for traditional mechanical connections. The smooth interior surface minimizes friction losses and prevents sediment accumulation, ensuring efficient fluid transport throughout the system's operational lifespan. Polypropylene piping systems find extensive applications in potable water networks, industrial chemical processing, laboratory installations, and HVAC systems. Their versatility extends to agricultural irrigation, aquaculture facilities, and pharmaceutical manufacturing environments. The material's inert properties make it suitable for food-grade applications and medical gas distribution. Environmental sustainability represents another significant aspect, as polypropylene piping systems offer recyclability and reduced carbon footprint compared to traditional materials. These systems demonstrate exceptional longevity, often exceeding 50 years of service life under normal operating conditions, making them cost-effective investments for long-term infrastructure projects.