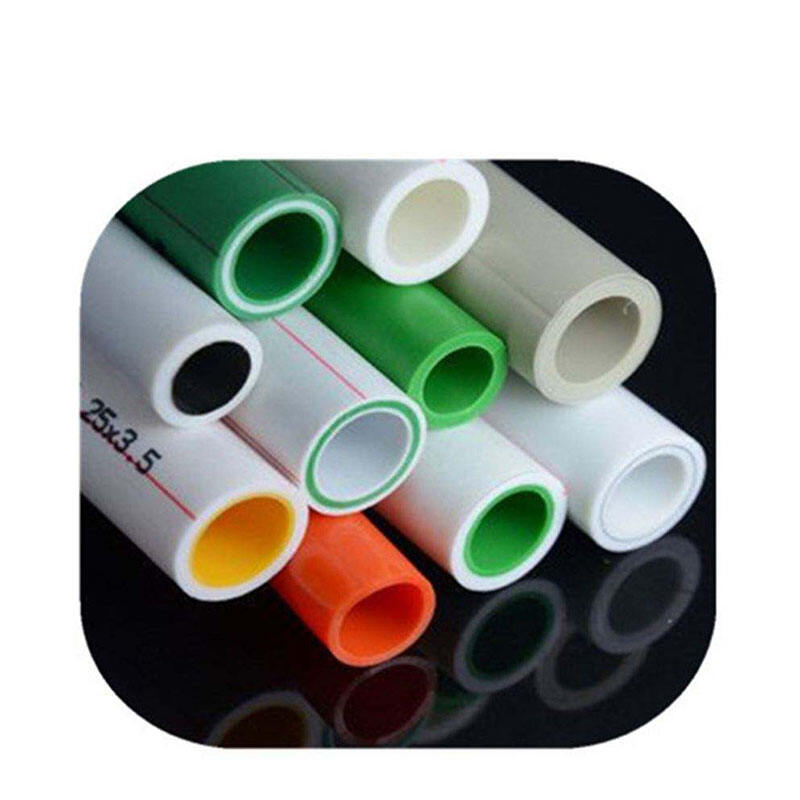

ppr pipe for water supply

PPR pipe for water supply represents a revolutionary advancement in modern plumbing infrastructure, offering exceptional performance for residential, commercial, and industrial applications. PPR, which stands for polypropylene random copolymer, is a thermoplastic material specifically engineered to meet the demanding requirements of water distribution systems. This innovative PPR pipe for water supply technology combines superior chemical resistance, thermal stability, and mechanical strength to deliver reliable long-term performance. The manufacturing process involves advanced polymer science that creates a homogeneous structure with consistent wall thickness and optimal flow characteristics. PPR pipe for water supply systems feature smooth interior surfaces that minimize friction losses and prevent bacterial growth, ensuring clean water delivery throughout the system. The pipe material exhibits excellent resistance to corrosion, scaling, and chemical degradation, making it ideal for various water quality conditions. Temperature resistance is another key technological feature, with PPR pipe for water supply capable of handling both hot and cold water applications up to 95°C under normal operating pressures. The fusion welding technology used for joining creates seamless, leak-proof connections that are stronger than the pipe itself. This welding method eliminates the need for mechanical fittings, gaskets, or adhesives that can fail over time. PPR pipe for water supply systems are available in various diameters and pressure ratings to accommodate different flow requirements and installation conditions. The lightweight nature of these pipes simplifies handling and installation while reducing transportation costs. Environmental sustainability is built into the design, as PPR pipe for water supply materials are fully recyclable and produce no harmful emissions during manufacturing or use. The smooth bore design maintains consistent flow rates and reduces energy consumption in pumping systems. Quality control measures during production ensure dimensional accuracy, pressure rating compliance, and material consistency across all PPR pipe for water supply products.