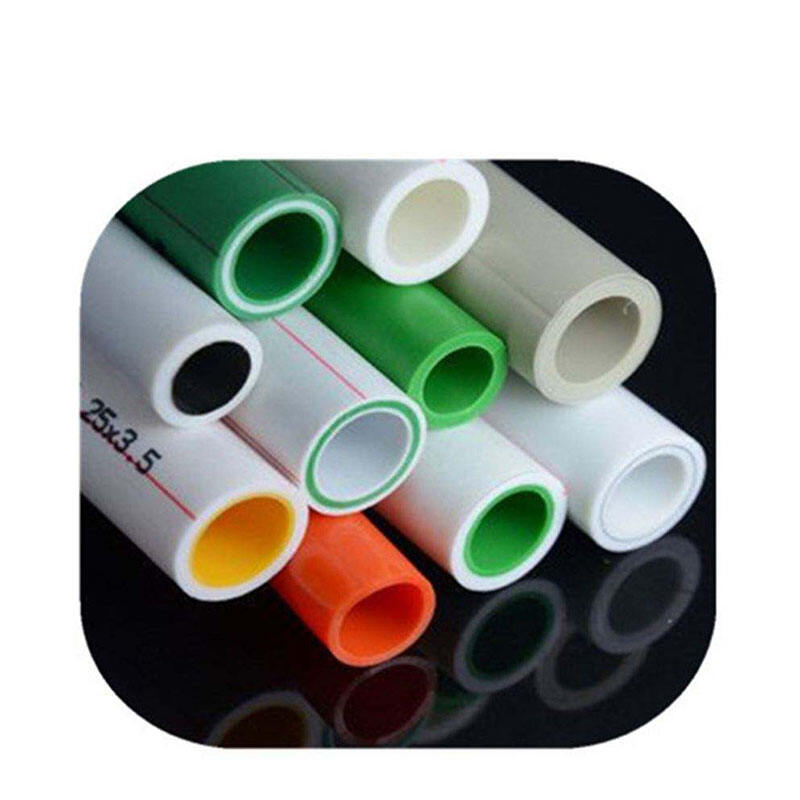

polypropylene piping

Polypropylene piping represents a revolutionary advancement in modern plumbing and industrial fluid transport systems. This thermoplastic polymer solution delivers exceptional performance across residential, commercial, and industrial applications through its unique molecular structure and manufacturing process. The polypropylene piping system consists of pipes, fittings, and valves engineered from high-grade polypropylene resin that undergoes precision extrusion and molding techniques. The main function of polypropylene piping centers on safe, reliable fluid conveyance for water distribution, chemical processing, drainage systems, and HVAC applications. Its technological features include superior chemical resistance properties that withstand corrosive substances, acids, and alkaline solutions without degradation. The material exhibits excellent temperature stability, operating effectively in ranges from sub-zero conditions to elevated temperatures exceeding 200 degrees Fahrenheit. Advanced manufacturing processes ensure consistent wall thickness, smooth internal surfaces that minimize friction losses, and precise dimensional tolerances for secure connections. Polypropylene piping incorporates innovative joining methods including heat fusion welding, mechanical fittings, and threaded connections that create leak-proof, permanent bonds. The applications for polypropylene piping span multiple industries including water treatment facilities, food and beverage processing, pharmaceutical manufacturing, swimming pool systems, radiant heating installations, and potable water distribution networks. Commercial buildings utilize these systems for hot and cold water supply lines, while industrial facilities depend on polypropylene piping for chemical transport and waste management. Residential applications include whole-house plumbing systems, hydronic heating circuits, and specialty installations requiring chemical resistance. The material's inherent properties make polypropylene piping ideal for environments where traditional metal pipes would corrode or contaminate fluids, establishing it as the preferred choice for modern piping infrastructure.