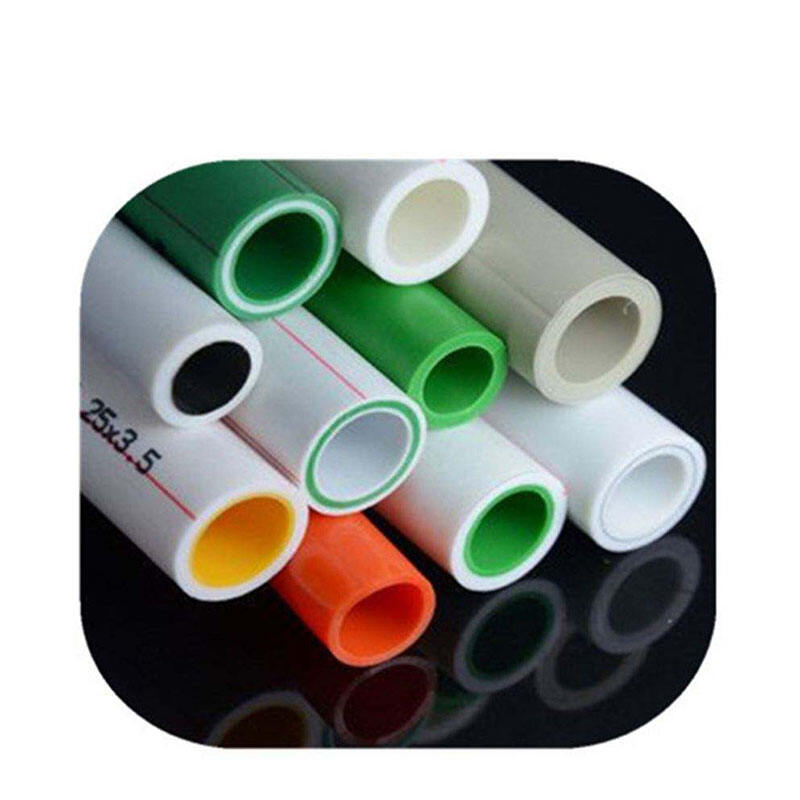

polypropylene plastic pipe

Polypropylene plastic pipe represents a revolutionary advancement in modern piping systems, offering exceptional performance across diverse industrial and commercial applications. This thermoplastic piping solution combines the inherent strength of polypropylene resin with advanced manufacturing techniques to deliver superior functionality in demanding environments. The polypropylene plastic pipe system excels in chemical resistance, making it an ideal choice for laboratories, pharmaceutical facilities, and industrial processing plants where corrosive substances are commonly transported. Its lightweight construction significantly reduces installation costs and labor requirements while maintaining structural integrity under varying pressure conditions. The polypropylene plastic pipe features excellent thermal stability, withstanding temperature fluctuations from sub-zero conditions to elevated operating temperatures without compromising performance. Manufacturing processes utilize high-grade polypropylene compounds that ensure consistent wall thickness and dimensional accuracy throughout the entire pipe length. These pipes incorporate fusion welding capabilities, creating permanent joints that eliminate potential leak points common in traditional threaded connections. The polypropylene plastic pipe system demonstrates remarkable flexibility during installation, accommodating building movements and thermal expansion without stress cracking. Advanced formulations include UV stabilizers and antioxidants that extend service life in outdoor applications. The smooth internal surface of polypropylene plastic pipe minimizes friction losses, improving flow efficiency and reducing energy consumption in pumping systems. Quality control measures during production ensure each polypropylene plastic pipe meets stringent industry standards for pressure ratings, chemical compatibility, and dimensional tolerances. Installation versatility allows for both above-ground and underground applications, with appropriate bedding and backfill procedures. The polypropylene plastic pipe system supports various joining methods including socket fusion, butt fusion, and mechanical fittings to accommodate different project requirements and site conditions.