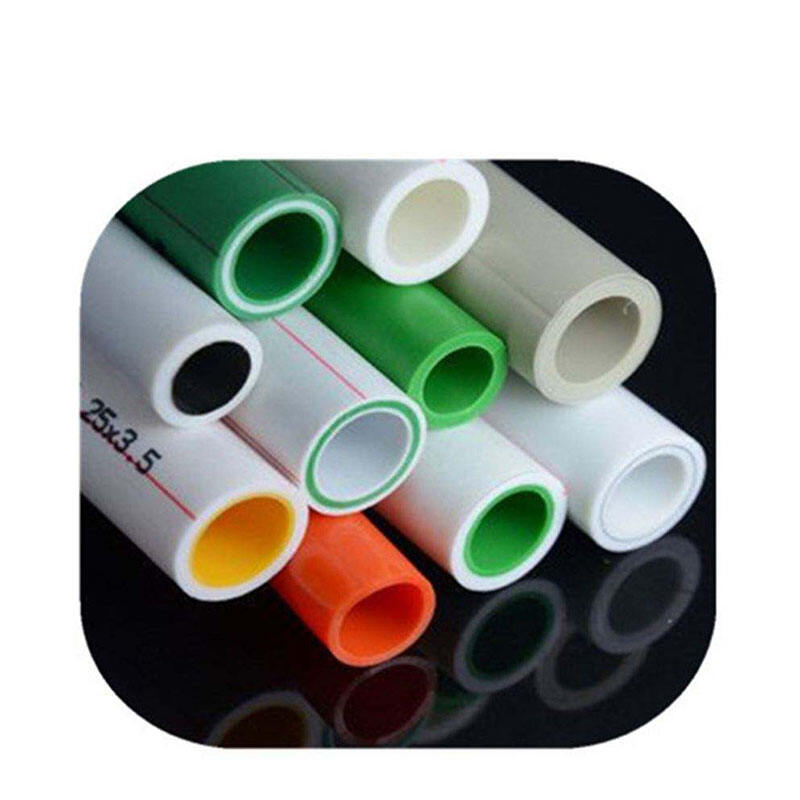

ppr pipes and fittings

PPR pipes and fittings represent a revolutionary advancement in modern plumbing and water distribution systems, offering superior performance through innovative polypropylene random copolymer technology. These specialized piping solutions deliver exceptional durability, chemical resistance, and thermal stability that surpasses traditional materials like PVC or metal alternatives. The main functions of PPR pipes and fittings encompass comprehensive water supply networks, heating systems, industrial fluid transport, and commercial building infrastructure. Their technological features include advanced molecular structure engineering that creates seamless fusion welding capabilities, ensuring leak-proof connections that maintain integrity for decades. The random copolymer composition provides excellent flexibility while maintaining structural strength, allowing PPR pipes and fittings to withstand temperature fluctuations from freezing conditions to high-heat applications reaching 95 degrees Celsius. These systems excel in residential plumbing installations, commercial water distribution networks, industrial chemical processing plants, and sophisticated heating circuits. The smooth internal surface of PPR pipes and fittings prevents scale buildup and maintains optimal flow rates throughout their operational lifespan. Applications span across diverse sectors including healthcare facilities requiring sterile water delivery, food processing industries demanding chemical-resistant materials, and residential developments seeking long-term reliability. The fusion welding technology creates permanent molecular bonds between PPR pipes and fittings, eliminating potential failure points common in threaded or glued connections. Environmental sustainability remains paramount, as PPR pipes and fittings contain no harmful chemicals, support recyclable manufacturing processes, and reduce material waste through extended service life. Installation versatility allows integration into existing systems or complete new construction projects, while the lightweight design reduces transportation costs and simplifies handling procedures for contractors and installers.