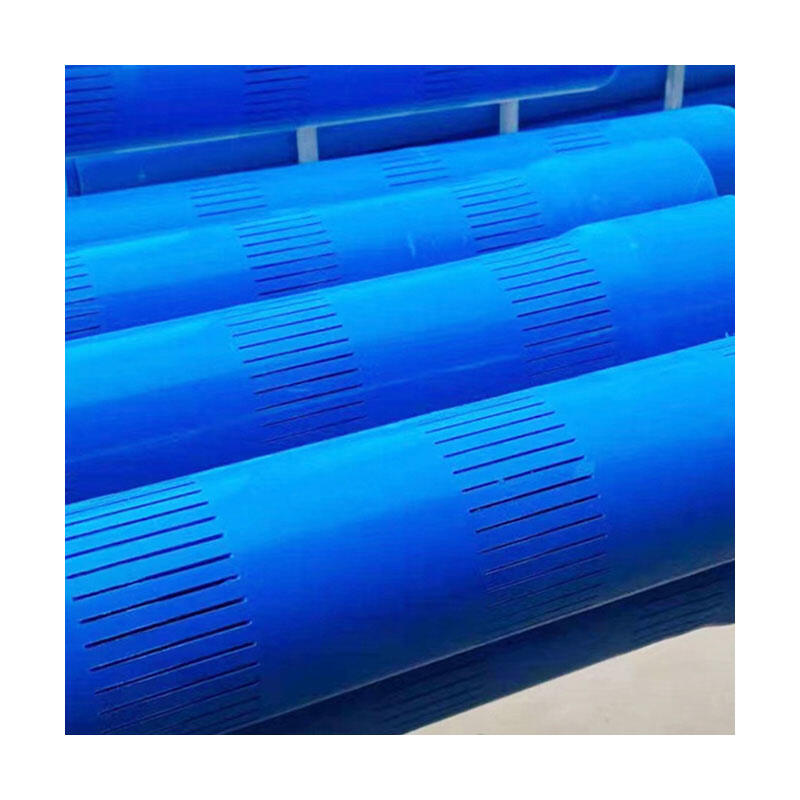

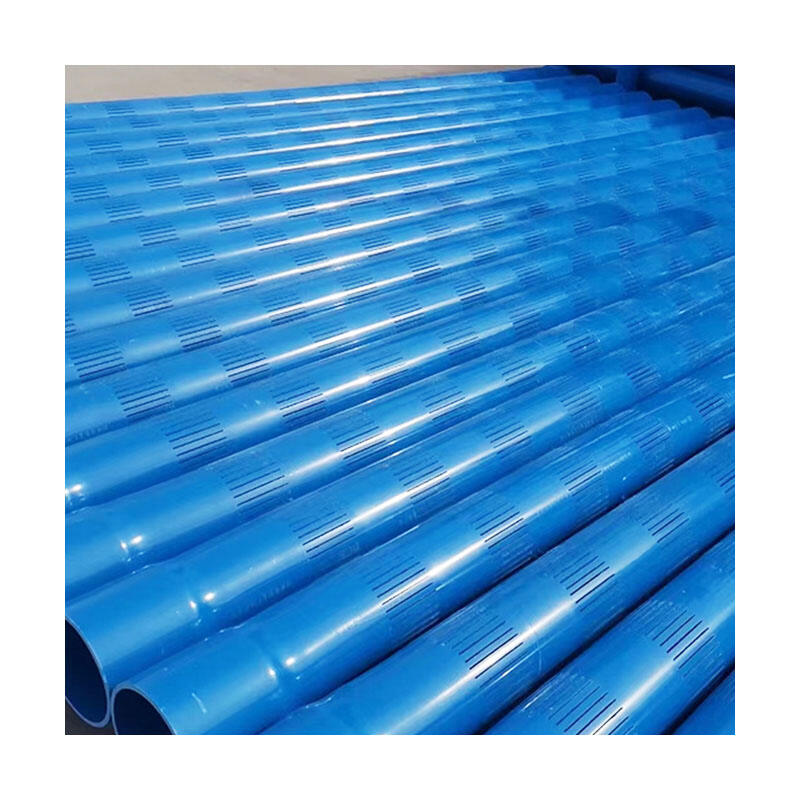

pvc well casing and screen pipes

PVC well casing and screen pipes represent essential components in modern water well construction and groundwater management systems. These specialized products combine durability, cost-effectiveness, and superior performance to create reliable water extraction solutions for residential, commercial, and industrial applications. The primary function of PVC well casing involves protecting the wellbore integrity while providing structural support throughout the entire depth of the well. This casing system prevents contamination from surface water and maintains the well's structural stability over extended periods. PVC well casing and screen pipes work together as an integrated system where the casing protects the upper portions of the well while screen pipes facilitate water entry at designated aquifer zones. The screen pipes feature precisely engineered slots or perforations that allow groundwater to enter while filtering out sand, sediment, and other unwanted particles. This filtration capability ensures clean water delivery and prevents pump damage from abrasive materials. Technological features of PVC well casing and screen pipes include advanced polymer formulations that resist chemical corrosion, UV degradation, and biological growth. The manufacturing process employs strict quality control measures to ensure consistent wall thickness, accurate dimensions, and reliable joint connections. Modern PVC well casing systems incorporate threaded connections or solvent-welded joints that create watertight seals preventing cross-contamination between different water-bearing formations. Applications for PVC well casing and screen pipes span numerous industries including municipal water supply systems, agricultural irrigation, industrial process water, geothermal installations, and environmental monitoring wells. These products excel in both shallow and deep well applications, accommodating various geological conditions and water quality requirements. The versatility of PVC well casing and screen pipes makes them suitable for temporary monitoring installations as well as permanent water supply systems designed for decades of reliable service.